Valmet is introducing new low-friction doctor blades to respond to customers’ ene...

Rayonier Advanced Materials plans to release its first quarter 2024 earnings on Tuesday...

Suzano Ventures, the corporate venture capital arm of Suzano, the world’s largest...

Georgia-Pacific's Albany Lumber has produced its 1 billionth boardfoot. The record-...

Valmet will supply a Valmet IQ Moisturizer system to Adara Pakkaus Oy in Finland. The s...

Acon Timber, the Argentine sawmill of HS Timber Group in Virasoro (province of Corrient...

Hygiene is a fundamental aspect of human health and well-being, and innovations in paper-based hygiene products have significantly contributed to enhancing personal and public health standards. These products, ranging from tissue papers to disposable wipes and sanitary napkins, play a vital role in maintaining cleanliness, comfort, and convenience in various settings, including homes, workplaces, healthcare facilities, and public spaces. The continuous evolution of paper-based

The packaging industry plays a crucial role in the sustainability efforts of the pulp and paper sector, with innovations in packaging lines driving significant advancements towards eco-friendly practices. In this article, we will explore the evolving landscape of packaging lines in the pulp and paper industry, focusing on the integration of sustainable materials, technological advancements, and operational efficiencies. By delving into the challenges faced, current innovations, successful case studies, and future opportunities,

Water plays a crucial role in the paper manufacturing process, serving as a medium for pulp production, bleaching, and various stages of papermaking. However, this reliance on water also poses environmental challenges, particularly regarding wastewater treatment and discharge. In recent years, paper mills have been embracing innovative technologies to enhance water treatment processes, improve efficiency, and reduce environmental impact. This article delves into the latest innovations driving water treatment in paper mills

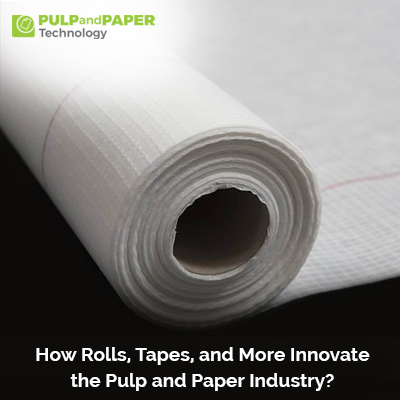

Rolls play a crucial role in the pulp and paper industry, serving as key components in various stages of production, from processing raw materials to converting them into finished products. Recent innovations in roll technology have significantly enhanced efficiency, quality, and sustainability in the industry.

The pulp and paper industry plays a vital role in modern society, providing essential products such as paper, cardboard, and various packaging materials. However, this industry is also known for its significant environmental impact, particularly in terms of waste generation and management. In recent years, there has been a growing emphasis on optimizing waste management practices within the pulp and paper sector to reduce environmental harm and improve overall sustainability.

"The Silyzer 300 is Siemens Energy’s latest product line in our portfolio of double-digit megawatt electrolyzers. It has several features that make it well suited for today’s green hydrogen production plants"

"AFT's proprietary simulation software called SimAudit™ helps in the evaluation and selection of appropriate equipment to fit the specific customer needs. We can simulate individual unit operations or an entire process line to accurately predict the benefits of our proposed solutions".

"As manufacturers, we ought to offer machines that are reliable, customizable and affordable so our customers can be competitive in this global landscape".

"We at Messe Muenchen India have been bringing the thought leaders, technology providers and government officials together at one platform to offer right technologies".

"We offer a complete package of deliveries from stock preparation lines to paper machines to papermaking auxiliary chemical plants and naturally to professional engineering services"

Metsä Group announces its plans for a significant investment program in its tissue paper business in the Mänttä mill to develop the sustainability of...

Crown Paper Mill has decided to invest in a second Valmet’s Advantage DCT tissue line including an extensive automation package, flow control valves a...

Argentinian leading packaging paper and tissue producer UnionPel selected Toscotec to supply a technological upgrade of PM1 at their Pacheco mill in t...

International technology group ANDRITZ has received an order from Moorim P&P, South Korea, to upgrade an evaporation plant at its Ulsan mill.