Optimizing Waste Management Practices in the Pulp and Paper Industry

Introduction

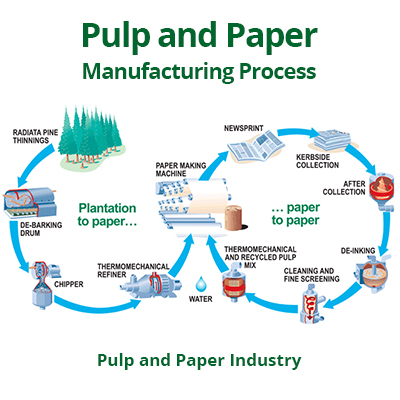

The pulp and paper industry plays a vital role in modern society, providing essential products such as paper, cardboard, and various packaging materials. However, this industry is also known for its significant environmental impact, particularly in terms of waste generation and management. In recent years, there has been a growing emphasis on optimizing waste management practices within the pulp and paper sector to reduce environmental harm and improve overall sustainability.

This article delves into the challenges faced by the industry, innovative waste management solutions, and the benefits of adopting such practices.

A. Challenges in Waste Management

The pulp and paper industry generates various types of waste throughout its production processes, including solid waste, wastewater, and emissions. Solid waste comprises materials like wood chips, bark, and paper trimmings, while wastewater contains pollutants such as organic compounds, suspended solids, and chemicals used in the production process. Emissions, including greenhouse gases and air pollutants, also contribute to the industry's environmental footprint.

One of the primary challenges in waste management for this industry is the sheer volume of waste generated. Large-scale paper mills can produce thousands of tons of waste per day, requiring efficient and sustainable disposal methods to prevent environmental degradation. Additionally, the diverse nature of waste materials, from organic to chemical substances, necessitates specialized handling and treatment approaches.

Traditional waste management practices, such as landfilling and incineration, have significant drawbacks in terms of environmental impact. Landfilling can lead to soil and water contamination, while incineration releases harmful pollutants into the atmosphere. Moreover, these methods do not align with the principles of circular economy and sustainable resource management, prompting the need for innovative solutions.

B. Innovative Waste Management Solutions

To address the challenges posed by waste management in the pulp and paper industry, various innovative solutions have emerged, focusing on waste reduction, recycling, and resource recovery. These solutions not only minimize environmental harm but also offer economic benefits and support the industry's transition toward a more sustainable future.

Waste Minimization Strategies:

a. Process Optimization: Implementing advanced technologies and process modifications to minimize waste generation at the source. For example, optimizing pulping and bleaching processes can reduce the amount of chemicals and raw materials required, leading to lower waste outputs.

b. Material Efficiency: Promoting the use of recycled fibers and adopting efficient papermaking techniques to reduce paper losses during production. Improving paper machine runnability and adjusting parameters like basis weight and moisture content contribute to material efficiency.

Recycling and Reuse:

a. Paper Recycling: Encouraging the recycling of paper and cardboard products to divert waste from landfills and reduce the demand for virgin fibers. Collaborating with recycling facilities and implementing collection programs for used paper materials.

b. Waste-to-Energy: Exploring waste-to-energy technologies such as biomass combustion and anaerobic digestion to convert organic waste into renewable energy sources like heat, electricity, or biogas. This approach not only reduces waste volume but also contributes to energy self-sufficiency.

Advanced Treatment Technologies:

a. Wastewater Treatment: Deploying advanced wastewater treatment systems, including biological treatment, membrane filtration, and chemical precipitation, to remove pollutants and improve water quality before discharge. Recycling treated water for process reuse reduces freshwater consumption.

b. Air Emission Control: Installing effective air pollution control devices such as electrostatic precipitators, scrubbers, and catalytic converters to capture and neutralize emissions like particulate matter, sulfur dioxide, and nitrogen oxides.

C. Benefits of Optimizing Waste Management Practices

The adoption of optimized waste management practices in the pulp and paper industry offers numerous benefits, encompassing environmental, economic, and social aspects.

Environmental Benefits:

a. Reduced Pollution: By minimizing waste generation and implementing efficient treatment technologies, the industry can significantly reduce pollution levels in air, water, and soil, leading to improved environmental quality.

b. Resource Conservation: Recycling paper fibers and recovering energy from waste materials conserve natural resources, including forests, water, and fossil fuels, contributing to conservation efforts and mitigating ecological impacts.

c. Climate Mitigation: Waste-to-energy technologies help mitigate climate change by reducing greenhouse gas emissions associated with traditional waste disposal methods like landfilling and incineration.

Economic Advantages:

a. Cost Savings: Waste reduction and recycling initiatives can lower production costs through decreased raw material consumption, waste disposal fees, and energy expenditures.

b. Revenue Generation: Selling recycled paper products and surplus energy generated from waste can create additional revenue streams for pulp and paper companies.

c. Compliance and Reputation: Adhering to stringent waste management regulations and demonstrating environmental responsibility enhances the industry's reputation and market competitiveness.

Social Impacts:

a. Health and Safety: Improved waste management practices contribute to a healthier workplace environment for employees by reducing exposure to hazardous substances and emissions.

b. Community Engagement: Engaging with local communities through sustainable initiatives, waste awareness programs, and environmental education fosters positive relationships and promotes social responsibility.

D. Case Studies and Success Stories

Several pulp and paper companies have successfully implemented optimized waste management practices, showcasing the feasibility and benefits of such initiatives.

Stora Enso:

a. Stora Enso, a leading global provider of renewable solutions in packaging, biomaterials, and paper, has invested in advanced recycling technologies to enhance circularity within its operations.

b. The company's recycling facilities process millions of tons of recovered paper annually, producing high-quality recycled fibers for use in new paper and packaging products.

UPM-Kymmene:

a. UPM-Kymmene, a Finnish multinational corporation, has adopted a comprehensive approach to waste management, focusing on waste reduction, recycling, and energy recovery.

b. Through partnerships with waste management providers and investments in biomass and biogas production, UPM-Kymmene has achieved significant reductions in waste sent to landfills and greenhouse gas emissions.

Smurfit Kappa:

a. Smurfit Kappa, a leading paper-based packaging manufacturer, has implemented closed-loop recycling systems across its facilities, ensuring the efficient utilization of paper fibers and reducing waste generation.

b. By optimizing material flows and collaborating with customers on sustainable packaging solutions, Smurfit Kappa has strengthened its environmental performance and market position.

Conclusion

Optimizing waste management practices in the pulp and paper industry is essential for mitigating environmental impact, promoting resource efficiency, and fostering sustainable development. Through waste minimization, recycling, advanced treatment technologies, and strategic partnerships, companies can achieve significant environmental and economic benefits while meeting regulatory requirements and enhancing stakeholder trust. The success stories of pioneering companies demonstrate that sustainable waste management is not only feasible but also a key driver of long-term competitiveness and resilience in the evolving global market.