How Rolls, Tapes, and More Innovate the Pulp And Paper Industry?

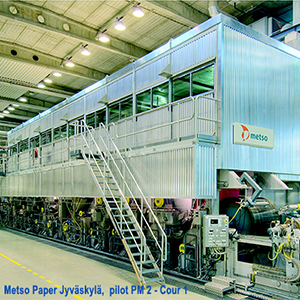

Rolls play a crucial role in the pulp and paper industry, serving as key components in various stages of production, from processing raw materials to converting them into finished products. Recent innovations in roll technology have significantly enhanced efficiency, quality, and sustainability in the industry.

One of the notable innovations in rolls is the development of advanced roll covers. These covers, made from materials like ceramics, polymers, and composite materials, offer superior wear resistance, thermal stability, and chemical inertness compared to traditional covers. This innovation has extended the lifespan of rolls, reduced maintenance costs, and improved overall process reliability.

Furthermore, the integration of smart sensors and IoT technology into rolls has revolutionized monitoring and maintenance practices. These sensors can provide real-time data on roll performance, temperature, vibration, and wear, allowing operators to detect issues early, optimize settings, and schedule maintenance proactively. This proactive approach has minimized downtime, increased productivity, and optimized resource utilization.

In addition to technological advancements, innovations in roll design have also contributed to the industry's progress. For example, the development of precision-engineered rolls with optimized geometries, surface finishes, and profiles has resulted in improved product quality, reduced energy consumption, and enhanced process control. These rolls are designed to deliver precise web handling, uniform coating, and efficient fiber processing, leading to higher yields and lower waste generation.

Tape Innovations Driving Efficiency and Sustainability

Tapes play a vital role in the pulp and paper industry, serving multiple functions such as splicing, bundling, sealing, and labeling. Recent innovations in tape technology have focused on enhancing performance, durability, and sustainability while addressing industry-specific challenges.

One of the significant innovations in tapes is the introduction of biodegradable and compostable tape materials. These tapes, made from renewable sources such as plant-based polymers, offer a sustainable alternative to traditional petroleum-based tapes. They can degrade naturally over time, reducing environmental impact and aligning with the industry's sustainability goals.

Moreover, advancements in adhesive technologies have led to the development of high-performance tapes with superior bonding strength, temperature resistance, and moisture resistance. These tapes are designed to withstand harsh processing conditions, ensuring reliable sealing, splicing, and packaging in paper mills and converting facilities. The use of such tapes has improved product integrity, minimized waste, and optimized packaging efficiency.

Another area of tape innovation is the integration of smart features, such as RFID tags and QR codes, into packaging tapes. These smart tapes enable automated tracking, traceability, and authentication throughout the supply chain, enhancing inventory management, logistics visibility, and anti-counterfeiting measures. By leveraging these technologies, companies can improve operational efficiency, streamline processes, and enhance product security.

Advances in Other Pulp and Paper Innovations

Beyond rolls and tapes, several other innovations are shaping the pulp and paper industry's landscape, driving efficiency, sustainability, and competitiveness.

One notable advancement is the adoption of digitalization and automation across production processes. Digital technologies, such as AI, machine learning, and data analytics, are being utilized to optimize resource allocation, predict equipment failures, and improve decision-making. Automated systems for pulp processing, papermaking, and finishing operations are enhancing productivity, quality control, and cost-effectiveness.

Furthermore, the industry is witnessing a shift towards circular economy principles, with an emphasis on waste reduction, resource efficiency, and recycling. Innovations in waste management technologies, such as anaerobic digestion, biomass conversion, and closed-loop systems, are enabling mills to convert by-products and residues into valuable resources, such as biofuels, chemicals, and renewable energy.

Additionally, advancements in papermaking processes, such as nano-fiber technology, micro-patterning, and surface treatment techniques, are leading to the development of high-performance specialty papers with unique properties. These papers are finding applications in diverse sectors, including packaging, filtration, electronics, and medical industries, driving market diversification and product innovation.

Conclusion

In conclusion, the pulp and paper industry is undergoing a transformative phase driven by continuous innovation in rolls, tapes, and other key technologies. These innovations are not only improving operational efficiency, product quality, and sustainability but also opening new opportunities for market growth and diversification. By embracing technological advancements and sustainable practices, the industry is poised to remain competitive, resilient, and environmentally responsible in the evolving global market landscape.