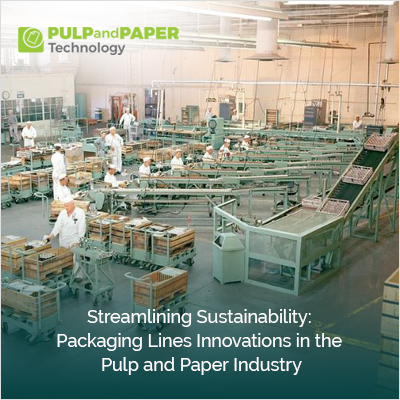

Streamlining Sustainability: Packaging Lines Innovations in the Pulp and Paper Industry

The packaging industry plays a crucial role in the sustainability efforts of the pulp and paper sector, with innovations in packaging lines driving significant advancements towards eco-friendly practices. In this article, we will explore the evolving landscape of packaging lines in the pulp and paper industry, focusing on the integration of sustainable materials, technological advancements, and operational efficiencies. By delving into the challenges faced, current innovations, successful case studies, and future opportunities, we aim to provide insights into how streamlining sustainability in packaging lines is reshaping the industry for a greener future.

A. Introduction to Packaging Lines in the Pulp and Paper Industry

In the world of packaging, the pulp and paper industry plays a crucial role in creating sustainable solutions. Packaging lines are the heart of efficiently packaging products, from boxes to bags and everything in between.

Overview of Packaging Processes

Packaging processes in the pulp and paper industry involve a series of steps from raw materials to the final product. These processes include printing, cutting, folding, and gluing to create various types of packaging that protect and showcase products.

Importance of Sustainability in Packaging

Sustainability in packaging is no longer just a buzzword – it's a necessity. With the rising awareness of environmental issues, the pulp and paper industry is shifting towards sustainable practices to reduce waste, conserve resources, and minimize environmental impact.

B. Current Challenges in Sustainability and Efficiency

Environmental Impact of Traditional Packaging Methods

Traditional packaging methods often rely on non-renewable resources and generate excessive waste. This results in deforestation, pollution, and greenhouse gas emissions, contributing to climate change.

Operational Inefficiencies in Packaging Lines

Inefficient packaging lines can lead to delays, increased costs, and wastage of materials. Streamlining operations and improving efficiency is crucial for reducing environmental impact and maximizing productivity.

C. Innovations in Packaging Line Technology

Advancements in Machinery and Equipment

Modern packaging line technology incorporates automation, robotics, and advanced machinery to optimize packaging processes. These innovations help speed up production, improve accuracy, and reduce energy consumption.

Integration of Smart Technologies

Smart technologies like Internet of Things (IoT) sensors and data analytics are revolutionizing packaging lines. By collecting real-time data, companies can make informed decisions to enhance efficiency, quality control, and sustainability practices.

D. Sustainable Materials and Practices in Packaging

Usage of Recycled and Biodegradable Materials

Switching to recycled and biodegradable materials is a game-changer for sustainable packaging. These materials reduce reliance on virgin resources, decrease waste in landfills, and promote a circular economy.

Implementing Circular Economy Principles

The concept of a circular economy focuses on reducing, reusing, and recycling materials to create a closed-loop system. By embracing circular economy principles, the pulp and paper industry can minimize waste, conserve resources, and create a more sustainable packaging ecosystem.

E. Automation and Digitalization in Packaging Lines

In the fast-paced world of packaging, automation and digitalization are the dynamic duo leading the charge towards streamlined sustainability. With the integration of cutting-edge technology, packaging lines in the pulp and paper industry are revolutionizing efficiency and eco-friendliness. Let's delve into how these innovations are shaping the future of packaging.

Role of Robotics in Packaging Processes

Robots are no longer just a feature of science fiction – they are now an integral part of packaging processes in the pulp and paper industry. From precise picking and packing to handling delicate materials, robots are enhancing speed, accuracy, and safety in packaging lines. With their ability to work tirelessly without breaks, robots are transforming the packaging landscape, providing a glimpse into a future where efficiency and sustainability go hand in hand.

Data Analytics for Efficiency Optimization

In the quest for operational excellence, data analytics is a game-changer for optimizing efficiency in packaging lines. By harnessing the power of data, companies can make informed decisions, identify bottlenecks, and fine-tune processes for maximum output. From predictive maintenance to real-time monitoring, data analytics is the key to unlocking the full potential of packaging lines, paving the way for a more sustainable future.

F. Future Trends and Opportunities for Improvement

As the packaging industry continues to evolve, future trends and opportunities for improvement are on the horizon, promising a more sustainable and efficient landscape. Let's explore the emerging technologies and strategies that are shaping the future of packaging in the pulp and paper industry.

Emerging Technologies in Packaging Industry

From blockchain traceability to 3D printing, emerging technologies are reshaping the packaging industry, offering new possibilities for sustainability and innovation. By harnessing the power of these cutting-edge solutions, companies can drive efficiencies, reduce waste, and meet the growing demand for eco-friendly packaging options. The future of packaging is bright with possibilities, thanks to these transformative technologies.

Potential Strategies for Further Sustainability Gains

To stay ahead of the sustainability curve, companies in the pulp and paper industry can explore a range of strategies for further gains in eco-conscious packaging. From implementing circular economy principles to investing in renewable energy sources, there are myriad opportunities to enhance sustainability practices and reduce environmental impact. By adopting a holistic approach to sustainability, companies can not only meet consumer expectations but also lead the way towards a greener future for the packaging industry.

In conclusion, the ongoing innovations in packaging line technology within the pulp and paper industry are not only enhancing efficiency and productivity but also paving the way for a more sustainable future. By embracing these advancements, companies can reduce their environmental impact, improve operational practices, and contribute to a healthier planet. As the industry continues to evolve, the integration of sustainable materials, automation, and digitalization will play a pivotal role in streamlining sustainability and driving positive change in the packaging sector.

FAQ

1. How are sustainable materials incorporated into packaging lines in the pulp and paper industry?

Sustainable materials are incorporated into packaging lines in the pulp and paper industry through various methods such as using recycled fibers, biodegradable coatings, eco-friendly inks, and adopting energy-efficient production processes.

2. What role does automation play in improving efficiency and sustainability in packaging processes?

Automation plays a crucial role in improving efficiency and sustainability in packaging processes by reducing manual labor, minimizing material waste through precise measurements and cutting, optimizing energy usage, and enabling real-time monitoring and adjustments for optimal resource utilization.

3. Can you provide examples of companies that have successfully implemented sustainable packaging practices in their operations?

- Procter & Gamble (P&G) uses recycled materials and innovative designs to reduce waste.

- Unilever focuses on biodegradable materials and refillable packaging.

- Patagonia uses recycled materials and encourages recycling.

- IKEA uses renewable materials and promotes responsible disposal.

- Nestlé uses recycled plastics and supports plastic waste reduction.

These companies showcase diverse approaches to sustainable packaging, from material choices to recycling programs, demonstrating the range of strategies available to improve environmental impact in packaging operations.

4. What are some future trends and opportunities for further enhancing sustainability in packaging lines within the industry?

Future trends for enhancing sustainability in packaging lines include biodegradable materials, circular economy practices, smart packaging, eco-friendly inks, reducing single-use plastics, collaborative initiatives, carbon neutral packaging, and consumer engagement.