Corrugated Boxes and Its Types

Corrugated boxes are regularly used as transportation containers. Any item at your favourite supermarket, premium store, or shopping mall were carefully delivered in boxes made of corrugated cardboard, which were manufactured and used for transportation purpose. Boxes provide an amazing measure of product protection by themselves but usually need internal segments such as cushioning, bracing and blocking to improve the protection of fragile products. The shipping hazards depend largely upon the particular logistics system being employed. Ordinary transportation containers require to print and label to identify the products, printed legal and regulatory information, and bar codes. Some boxes are designed for the display of products on the shelf.

Corrugated is a strong, light-weight and durable material made up of three layers of brown craft paper. It includes a process for pulping wood pieces into a strong board that resists tearing, splitting, and breaking. From a paper mill, rolls of craft paper are transported to a corrugating plant. In the manufacturing process, layers of craft paper are folded and glued to make corrugated cardboard, which is then built into corrugated boxes. Fast-growing pine trees are the primary raw material to make corrugated cardboard. Glue made of corn starch is used to bond the corrugated medium, as more glue is used it is delivered as a dry powder to store until the usage. Paraffin waxes or vegetable oils are used to make a water or grease-resistant container for food products.

Types of corrugated boxes

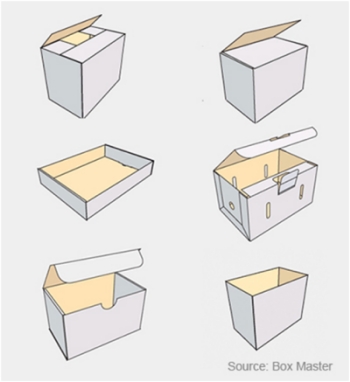

Regular Containers:

This is the common type of box style efficiently designed for packaging. All covers are the same length from the score to the edge. These are used for a variety of products shipping, small and individual items such as cups, glasses and books can be easily packed. A very little manufacturing waste is produced in the making of these boxes. These boxes can be folded and stored also, can be shipped as flat cardboard.

Corrugated trays:

Perfect for shipping small, lightweight loads. They are beneficial, with product visibility and easy handling are of prime importance. Used in food and beverage industry products such as bottled water, soft drinks, snacks, and bulk packaged foods. It also provide extra stability and safety while moving plants or other agile objects.

Telescope type box:

The telescoping corrugated box design is constructed with an adjustable 2-piece F.O.L (full overlap) set designed to fit tall and odd-shaped products. The set is combined with one inner and one outer box used together to create a telescoping corrugated box.

Half Slotted Containers:

Half slotted containers are containers that have only one set of flaps. The opposite side of the box is open, which allows it to slide over an item. Bottom flaps are with uniform length and meet the centre of the box while absent top flaps leave the top of the box uncovered. They are highly efficient, durable, and versatile offering many different applications for storing and transporting. Mostly used for shipping of large and heavy products such as refrigerators and washing machines.

Slide type Corrugated box:

Sliding corrugated boxes are gift boxes, sleeves, slipcases, which is one of the most featured box products. Also known as drawer paper box, slipcase and matchbox style. It is widely used for packaging of up-scale books, software, jewellery, electronic products and cosmetic products.

Custom Die cut:

Custom corrugated boxes developed to exact specifications depending on customer requirements. It can be manufactured with a variety of box styles, full colour and available in all custom sizes. Used for unique products with specific requirements such as luxurious product boxes, doll product boxes, and premium product boxes.

Full Overlap Corrugated Box:

The outer flaps overlap the full width of the box making it exceptionally resistant to rough handling. Overlapping provides added cushioning and protection. All flaps are the same depth, and their depth equals the width of the box. These are used for heavy objects which require extra support.

Roll End Tuck Top:

Roll end tuck top boxes are unplugged from the top like a treasure chest. These need to be folded when assembled. Such style provides an extremely strong structure which is why it can manage heavy duty item. Mostly used for cosmetics, food and retail product packaging, vitamin packaging, coffee packaging and tea packaging.

Folder type corrugated box:

This type of boxes has a flat bottom that is rigid. The side surfaces are joined to the ends of the corrugated cardboard at the bottom. The design of the boxes can be enhanced by adding holders, locks and display panels according to the requirements. They are normally designed to pack large or irregularly shaped products.