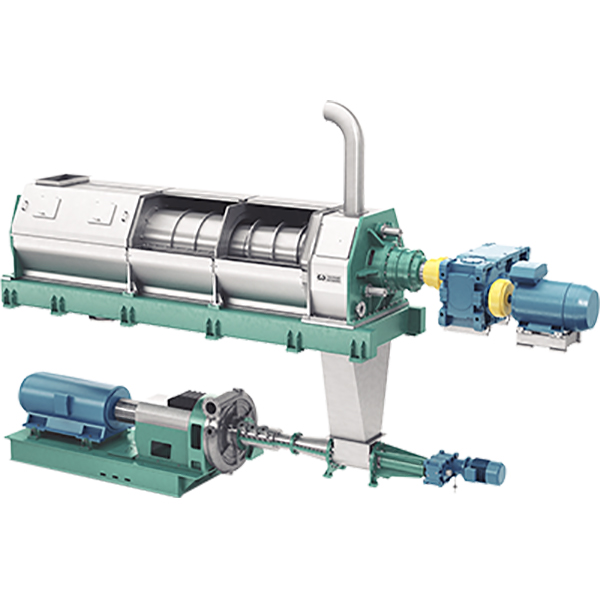

Ultra Compact Dispersing System (UCD)

Ultra Compact Dispersing System (UCD)

The UCD system consists of only three machines: screw press, infeeder/steamheater, and disperser. This solution offers the most compact design possible, something that saves both plant space and investment cost. Retention time is 5–10 seconds at a temperature of up to 110°C (230°F).

The system is further described below – with treatment steps for dewatering, heating and dispersing.

Dewatering zone

Screw press

Dewatering is made to thicken the pulp consistency from as low as 3% and up to 35%. A high consistency pulp entering the heating zone will ensure a low steam consumption, and a better dispersion result.

Heating zone

Infeeder steamheater

The Ultra Compact Disperser System consists of only three machines. Pre-heating is made in a combined infeeder steamheater, which is the only step between the screw press and the disperser. This solution offers the most compact system design possible.

Dispersing zone

Disperser

The fibers pass through a narrow gap between rotating discs, where any impurities are disintegrated to an invisible size. The devil-tooth pattern of the discs is optimized for each pulp mixture in order to achieve a gentle treatment of the fibers. Adjustment of the disc gap can be done on-line with an accuracy of 0,01 mm.