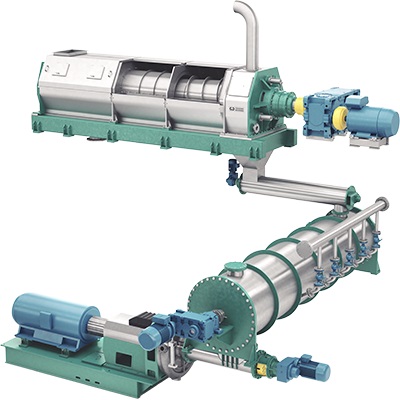

Compact Dispersing System (CDS)

The CDS is the only non-pressurized system. This principle allows for a more compact design: a conveyor can be used to replace both the plug screw and the shredder, and there is no need for pressure vessels or sealings for HC discharge. The non-pressurized concept gives a low steam consumption, and the design also allows for existing dewatering equipment to be used. Retention time is 20-30 seconds at a temperature of up to 95°C (203°F).

The system is further described below – with treatment steps for dewatering, heating and dispersing.

Dewatering zone

Screw press

Dewatering is made to thicken the pulp consistency from as low as 3% and up to 35%. A high consistency pulp entering the heating zone will ensure a low steam consumption, and a better dispersion result.

Heating zone

Conveyor

The Compact Dispersing System is a non-pressurized system and therefore a conveyor can be used to replace both the plug screw and the shredder. This gives a more compact solution for feeding to the pre-heater.

Pre-heater

The pulp is heated to an even temperature of up to 95°C, depending on raw material. Strength properties are weakened, and an improved dispersing result can be achieved.

Dispersing zone

Infeeder

The infeeder feeds the pulp from the pre-heater to the disperser. The infeed zone of the disperser has patented features that decreases risk of blocking, and contributes to a low energy consumption.

Disperser

The fibers pass through a narrow gap between rotating discs, where any impurities are disintegrated to an invisible size. The devil-tooth pattern of the discs is optimized for each pulp mixture in order to achieve a gentle treatment of the fibers. Adjustment of the disc gap can be done on-line with an accuracy of 0,01 mm.