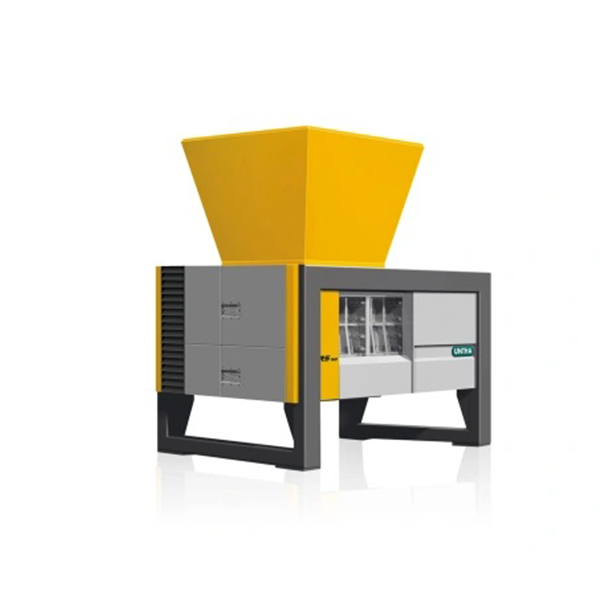

Shredder RS150

The powerful shredder RS150 for metal, tyres, scrap and particularly hard applications.

What distinguishes the RS150 shredder

-

4 x 80/4 x 45 kW Rated capacity

-

700 x 1.050 mm Feed opening

-

40-100 mm Fraction Sizes (based on the screen)

For particularly tough applications

The shredder RS150 is the largest UNTHA four shaft shredder, and has been developed for especially difficult applications where high throughput performance, high availability and low maintenance costs are all required. The drive system with water-cooled synchronous motor ensures a particularly low energy consumption with substantially higher efficiency in comparison to conventional diesel-powered drive variants.

Advantages of the Shredder RS150

At the heart of this shredding technology for particularly difficult applications is the energy-saving UNTHA Eco Power Drive. The drive concept of the system ensures that the cutter shafts are stopped as soon as a foreign object is detected in order to protect the machine cutting tools from damage. In addition, this drive permits frequent reversing, which is particularly beneficial when shredding problematic materials such as during metal recycling.

The throughput can always be optimally configured for the material to be shredded using the variable speed setting option for the cutting shafts. Because, in contrast to fast-running systems, no wear parts such as couplings, belts, shear pins or flywheels are required, this machine’s susceptibility to faults is reduced to a minimum. High availability with a high degree of efficiency, low energy consumption and simple maintenance make the RS150 an efficient workhorse - whether for industrial applications or big waste disposal companies.

Tough machine for many applications

There are hardly any limits to the application possibilities of the RS150 shredder. The largest of our four shaft shredders is capable of shredding quite simply everything which is submitted to recycling plants, and ranges from metals via plastics, right up to waste products which require further processing.

The range of materials starts with non-ferrous metals such as profiles, sheets, housing, aluminium rims and pipes, and continues with electronic scrap such as IT and telecommunications devices, entertainment electronics, electrical and electronic tools, right up to hazardous waste such as filled metal barrels and IBCs, radioactive waste, workshop waste, batteries, hybrid cells, hospital waste, right up to cables made with copper and aluminium and difficult applications such as sprung mattresses, reject materials and pulper ropes. This machine is a true powerhouse for the special challenges inherent in industrial recycling.

Which materials can be shredded?

-

Problematic Materials

-

Electronic Waste (WEEE)

-

Metal