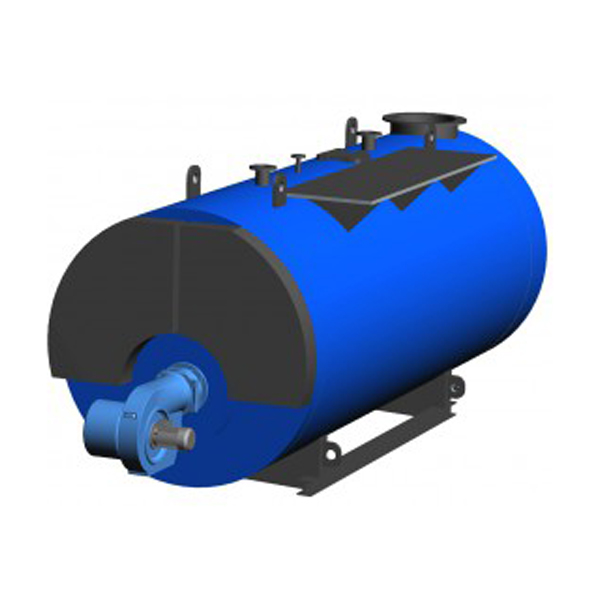

Hot Water Boiler PB-H

Hot-water and hot-water three-pass boilers for gaseous and liquid fuels.

According to the requirements of the ČSN EN 12 953 standard and the EC Directive 97/23

Construction

The boiler body consists of a cylindrical casing, two reinforced bottoms, a symmetrically placed flame, a water-cooled reversing chamber and an annular bundle of second and third draft heat pipes. The front reversing chamber is uncooled, closed by a door allowing cleaning of heating surfaces. The flue gas outlet from the boiler is provided by a smoke collector in the rear part of the boiler. Flue gas outlet through a flue with upper or rear outlet.

Equipment

The boiler body is equipped with a safety valve and drain, the outlet and return neck are equipped with extensions with weld-on pieces for the placement of measuring and control elements. An injector is located below the return water inlet to increase the inlet temperature.

There is also a pressure limiter for hot water boilers, hot water boilers are additionally equipped with a temperature limiter up to 110 ° C.

Manholes and inspection openings are used for internal inspection of the boiler.

Efficiency

The heat contained in the flue gases leaving the boiler can be transferred to the return water in the flue gas exchanger. The energy obtained in this way increases the efficiency by up to 7% and thus reduces fuel consumption.

Economizer

Complements the basic design of PB-V and PB-H boilers. It can be integrated into the flue gas collector or placed separately at the flue gas outlet.

Provides highly efficient heat transfer - countercurrent principle. It consists of bundles of ribbed or smooth pipes in the flue, which open into water chambers.

Flue gas exchanger connection

With regard to the boiler output and economy of design, two basic ways of exchanger connection are distinguished.

Full flow version - all return water flows through the exchanger, where preheating takes place.

Version with partial flow - only a part of the return water flows through the exchanger (10-30%), before entering the boiler, the rest of the return water is mixed with the heated water from the exchanger. This design is mainly used for boilers with a higher flow of circulating water.

Modification

The design of the boilers allows the use of an identical design for hot water and hot water boilers up to a pressure of 16 bar.