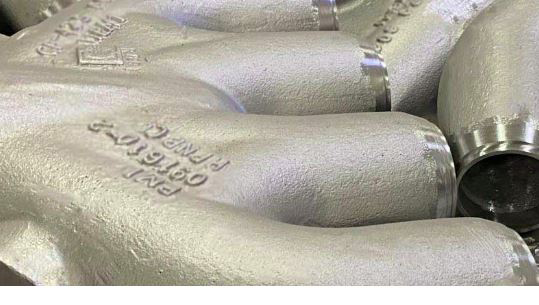

Sand Casting

Sand casting as a technology has existed for thousands of years and is a preferred metal casting process to produce shaped parts that weigh from less than a pound to thousands of pounds. Sand casting is versatile and cost effective even for low volumes because of low tooling cost. Nearly any part configuration made using another metal casting process can be reduced to a pattern and created as a sand casting.

In sand casting, a pattern of the desired finished part including the metal delivery system (gates and risers) is constructed out of hardwood, urethane, metal, or foam. Sand containing bonding material to maintain shape is packed around the pattern. The pattern is then removed from the bonded sand, leaving a cavity in the mold in the shape of the part. Molten liquid metal is poured into the cavity, and the metal solidifies. The sand is then removed through a shakeout process. Other cast attachments including the metal delivery system are removed, leaving the desired part.

Internal passageways including intricate structures can be included in sand casting by adding cores. This makes sand casting a popular choice for pump and valve applications. Sand castings are typically at least partially machined before use.

MetalTek produces sand castings up to 15 ft. (4.6 m) linear with ship weight up to 18,000 lbs. (8,165 kg).

See the video to the right to learn more about sand casting.

Patternless Molding

As an alternative to packing sand around the pattern, many customers take advantage of MetalTek’s Patternless Molding technology. A reverse of the casting is machined from sand to create the mold, rather than forming sand around a pattern. Production then proceeds normally. Timing is quicker than traditional sand casting, design changes are easy to implement, and hard patterns need not be stored or maintained.

Sand Casting Video

When To Use Sand Casting

- External shaping exists

- Internal structures and passageways are used

- Desired size ranges from a few pounds to 18,000 lbs. (8,165 kg)

- As-cast surface finish of 250 – 500 RMS is acceptable

- Post-cast machining is acceptable to achieve desired surface finish

- Extremely tight tolerances are not required

- Frequent design changes are expected

- Tooling and pattern costs for investment casting are too high

- Periodic cost of maintaining the tooling and pattern is acceptable

- Converting multi-piece component to a single casting