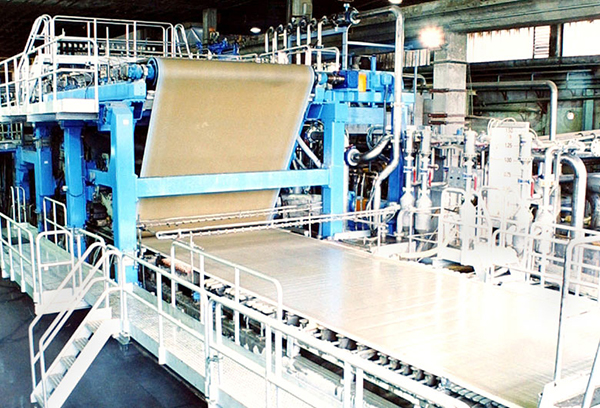

FLAT BOARDS

The tensioners and compensators of the TC series, in the different construction forms, are designed to be used in all phases of the continuous machine processing cycle where it is necessary to control the tension of a cloth or felt within a range of values set by the operator. In addition, the tensioners offer the possibility to control the "line" by means of the misalignment of the tensioner roller, which allows the compensation of the difference in development of the felt / cloth.

The production of these accessories is conceived with a view to optimizing the production process: each individual tensioner and / or compensator tensioner is designed and positioned so that it can maximize the efficiency of the system.

From the pursuit of this objective, a complete range of machines is born which take into account all the fundamental parameters:

- the section of use in the paper machine;

- the choice of the optimal material;

- the accuracy of the necessary control / adjustment;

- the machine table continues.

SPECIFICATIONS

The tensioners, typically used on flat tables, are made of stainless steel, while the compensator tensioners can be made of stainless steel or carbon steel, if used respectively for the press section or in the dryer. Both machines can be automatic or manual. The automatic control of the cloth / felt tension can be both electronic (with load cell) and pneumatic (torpress or pneumatic cylinders), according to the need for precision and the sectors of use.

The electronic compensators, in particular, offer a series of advantages such as:

- reduction of steam consumption in the drying room;

- reduction in the number of breakages;

- greater ease of queue passage;

- increase in the life of the cloths and felts;

- increased bearing life;

- better paper quality.

The correction of the ruler in the tensioners is carried out with the aid of a jack and screw which limits the adjustment range of the roller and at the same time measures its misalignment. This adjustment can be manual or motorized and the misalignment measurement can be visually or remotely for the hardly accessible sections of the machine.