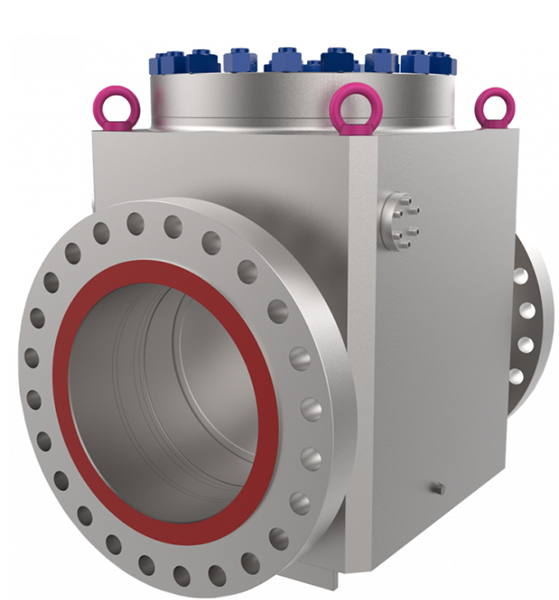

SWING CHECK VALVE

Swing check valves are a trusted choice for general-purpose use in both upstream and midstream applications, available in both forged or cast materials, and the design ensures total reliability for high pressure and high temperature services. The swinging action of the disc away from the seat allows forward flow and when the flow is stopped, the disc returns to the seat, preventing backflow. Swing check valves are suitable for installations in lines where pigging operations are required for various maintenance services. The piggable design makes the swing check valve ideal for installation in riser pipelines and subsea applications.Convenience of operation and simple in-line maintenance are essential features of our design. Internal parts can be inspected and repaired without removing the valve off the pipeline even where space is restricted as in the top entry trunnion ball valve construction.The valve can be installed in both vertical and horizontal positions and offers unsurpassed quality and reliability– while the simple design minimizes maintenance costs. Material selection is fully customizable to meet customers project specifications.

SERIES

CHK

VALVE DESIGN

based on API 6D and customer requirementsbased on API 6A and customer requirements

TEMPERATURE RANGE

-150 to 428°F (-101 to 220°C)

SIZE

NPS 1.13/16- 21.1/4 (DN 46-540)NPS 2 - 36 (DN 50-900)

PRESSURE RATING

ASME 150 - ASME 2500API 5000-API 15000

FACE-TO-FACE

As per API 6D standard or as Velan standard

END CONNECTIONS

RF, RTJ as per B16.5 &B16.47BW, Butt Welded as per B16.25Hub connection6B, 6BX as per API6A

BODY DESIGN

forged or cast one-piece

SEAT DESIGN

Metal-seated with hard facing on Disk and SeatWelded-in-seat ring

FEATURES

Easy in-line maintenance as in Top entry ball valve constructionSuitable for horizontal and vertical (flow-up) installationSuited for low velocity serviceFully piggable design Secondary seals in pure Graphite De-clutchable device for lock opening during pipeline cleaning

OPERATOR

automatic

TESTING & CERTIFICATIONS

Compliance with API 6D & ISO 5208 & API 598 inspection and testingCompliance with API 6A inspection and testing Fire safe and fire tested as per API 6FA/ 607PED 2014/68/UE Available as per API 6A standard:Product specification levels PSL 1, 2, 3, 3G, and 4Performance requirement levels PR1, PR2Design validation as per PR2F