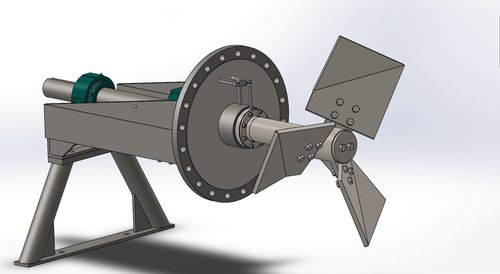

Side Insert Agitators

The James Brinkley Company side insert agitators have evolved over the years while retaining the attributes that they are known for: Strength and Simplicity of design. They come in sizes from 18” to 72” in diameter.

A-36 structural steel construction housing with ANSI steel flange tank connection faced with stainless as required. An outer support bracket is provided. An optional wall insert with stainless steel contact parts is available.

Large AISI Stress proof or 4140 steel shafts protected by replaceable stainless steel tubes and sleeves. Steel provides superior fatigue and shock resistance. Shafts are designed to operate below fatigue limits with less than 0.001” deflection at the stuffing box.

Stuffing boxes and seals come in either cast or stainless steel construction. They can take 4 square packing rings or an optional mechanical seal. A split ryertex throttle bushing is provided in the stuffing box to limit flush water use and support the shaft under shock load.

Cast glands with brass gland studs and nuts are standard. Optional split glands are available. Replaceable stuffing boxes are also available as options.

Brinkley propellers come in either adjustable pitch or fixed pitch blades.

Adjustable pitch blades provide the highest efficiency possible since power input can be adjusted to process requirements. They also allow flexibility for the inevitable process change of the future. Cast steel or stainless steel blades and hubs provide superior section thickness and resistance to shock and fatigue loads over fabricated fixed blade propellers.

Spherical roller bearings sized for L-10 lives of over 100,000 hours with occasional heavy shock loading. Bearings are protected by the best seal available from the manufacturer and the shaft is provided with a rubber slinger. All bearings are Rexnord or Link-Belt, or your mill standard. Brinkley can also provide, as an option, a UHMW labyrinth diaphragm at low cost to protect the bearing.

Pillow block units are accessible for removal and inner bearings can, optionally, be split type spherical roller bearings if desired.

All shafts are stepped to provide short bearing pulls and all bearings are replaceable with shaft in place.

Brinkley agitators can either be direct or belt driven.

Gear drives should be mounted independently with the drive motor on a separate base. Brinkley will provide your mill standard drive in parallel shaft or other configuration as required.

V-belt drives and adjustable steel motor mounts are mounted integral, or piggy back, up to 100 HP. Above this size, we suggest a separate adjustable motor base and support. Drives use a 1.5 service factor based on motor HP and include taperlock sheaves, 3V, 5V or 8V belts and guard.

Optional Features:

Extraction fittings can be added to the agitators to allow suction lines to be placed in a close area with an agitator, such as a couch pit. Fittings are constructed of ¼” stainless steel plate, usually with 1” diameter holes and cleaned by a heavy wiper bar rotating on the shaft. Extraction fittings are made to large diameters to accommodate high pump out rates and include a chamber to stabilize flow behind the suction plate and feed the discharge nozzle. Discharge nozzle outlets are fabricated from stainless steel.