Articles

Role Of IoT In Pulp And Paper Industry

The Internet of Things (IoT), in a few short years, has changed the way that organizations do business with both their customers and each other. In manufacturing, the Industrial Internet of Things (IIOT) is a way to digital transformation. A network of sensors is employed by Industrial IoT to collect critical production data that use cloud software to turn this data into valuable insights about the efficiency of the manufacturing operations. Industry 4.0 is the main reason for the evolution of smart industries and smart manufacturing. This industry 4.0 gives the pathway to the internet of things, cloud manufacturing systems, and smart industry. These tools help the company for easy monitoring and to increase their production. The introduction of the internet in the manufacturing process is the new transformation that is ongoing. This will not only increase productivity but also efficiency and flexibility.

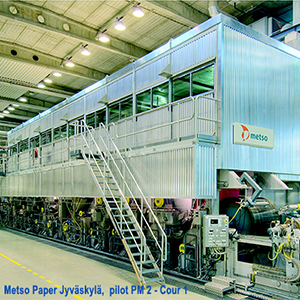

The role of IoT in the pulp and paper industry is very crucial. To obtain the best possible performance, continuous technology improvement is ongoing in the pulp and paper industry. There are many critical applications in the pulp and paper industry to measure the severe process condition, such as aggressive pulp slurry with extremely high pressure and temperature condition, corrosive chemicals. The key to optimizing the performance of plant operation and process control is stable and accurate control and measurement in these severe process conditions. Digital technology is being adopted by the pulp, paper, fiber, and packaging industry. This technology is leading a transformation to drive down costs, increase throughput, and gain a competitive edge with customers.

The pulp and paper industry is evolving globally, presenting technology suppliers and industry participants with both challenges and opportunities. The pulp and paper production, in general, are shifting from North America and Northern Europe to large, integrated mills in rising economies in South America and Asia. The markets in Japan, Western Europe, and North America are shrinking or stagnating across the board. The markets for packaging materials and hygiene-related paper products are growing, while the global market for newsprint is shrinking, due to the shift to digital media and communications.

Industry 4.0 In Pulp And Paper Industry

Today's paper industry stands ready to engage in its fourth industrial phase i.e. Industry 4.0. Industry 4.0 represents the next industrial revolution. It will very soon link product customization with large production series, linking machines to machines and products to services. The European pulp and paper industry, today, is in full transformation. With an increase in global competition and policy pressure, both market and consumer needs have evolved. Hence, to remain competitive, the industry has to innovate. Apart from addressing not only services and products, processes, innovation can also address business models, education and workforce training. As a result, our industry experiences huge potential in "digital", instead of treating it as a trend we are forced to struggle with.

Structural demographic changes, resource scarcity, and environmental issues are affecting us globally. At the same time, as competition increases, the companies are continuously forced to become ever more effective and there's increased pressure on high-cost regions like Europe. A key role will be played by Industry 4.0 in the pulp and paper industry and the digitalization of manufacturing in helping develop solutions to these challenges. From forests to end consumers, the whole process of papermaking will be revolutionized and the complete eco-system will be driven by real-time communication. Through sensors, the equipment will interact with its environment, it will communicate with other machines and trigger actions or reactions. Companies and industries who will be able to quickly adapt to the digitalized world and fully exploit its opportunities will be on the brighter side.

Paper Industry 4.0

With the digitalization of production processes, new roles and responsibilities will be created, potentially requiring various skill sets. When thinking about the future possibilities of Industry 4.0 in the paper industry's value chain, many opportunities do exist from raw materials to the consumption of the product by consumers. As equipment and production sites can interact without human interaction and make their own decisions, the operational purchasing functions and replenishment might be reduced. What changes do you think could be seen with digital transformation in the Paper Industry 4.0? Well, the answer lies below.

Digital Transformation In Paper Industry

Beginning with raw materials, the real-time information could be gathered about the condition, amount, and maturity of the tree stock. The optimal signal information or harvesting time could be transmitted and this information would then be passed through the whole value chain. As a result, wherever necessary, the processes could be adapted by the parties involved. In the same way, a real-time connection could be established for the suppliers to consumers, paper producers, and hence they would be able to react without delays to their customer's requirements. The supplier could immediately identify the need for quality issues or material replenishment by monitoring the production process, sales forecasts, and a customer's finished goods inventories.

On the production side too, the digital transformation in the paper industry can also be seen, as machines will be able to perform work with minimal or more targeted human intervention. Based on historical and real-time information about supply and demand, the production would be optimized. This would allow full transparency of capacities, costs, and customer needs. Based on real-time input, new algorithms would be developed and continuously updated. The logistics can become more self-organized and flexible, based on real-time information about shipment requirements. This would allow for a better allocation of higher fill rates, capacities, increased shipment accuracy, and hence lower claim levels. The route planning about conditions at pick-up and recipient sites could also be optimized. The customers will be able to access real-time information about demand and supply. Better planning and fulfillment against requirements can be allowed through direct and open communication between end consumers, paper producers, suppliers, and customers. The information about demand changes can be transmitted to all other supply chain participants, making it possible for them to produce and deliver accordingly. Better information about the application of products or the usage can be included in customer and product development processes.

The paper industry will be exemplified by self-organized intelligent "eco-systems", in the future. The players along the entire value chain will develop interconnected clusters, continuously sending and receiving information to and from each other. With regards to Industry 4.0, the pulp and paper industry is still at an early stage. Unlike other sectors such as aerospace, IT and the automotive industry who have already reached the stage of business plan development, the pulp and paper industry is still developing strategic awareness, as there are unconnected projects yet. By connecting all the participants in the value chain, Industry 4.0 will transform the way people communicate, consume and do business. Doing this would provide huge opportunities for the pulp, paper, and packaging industry.

The main opportunities provided by Industry 4.0 on the cost side, are based on the efficient use of available resources and optimized processes. The availability of smart equipment and vast amounts of data, supported by the ability to analyze it will make it possible. By removing the boundaries between different players in the value chain and improving the information flow among them, the companies will become more flexible to changing market circumstances and customer needs.

|

Read More: Digital Transformation in Paper Mills: Leveraging Industry 4.0 for Efficiency |