Digital Transformation in Paper Mills: Leveraging Industry 4.0 for Efficiency

Introduction

In an age marked by swift technological progress, the paper industry is undergoing a significant evolution. Conventional paper mills are actively adopting digital transformation as a means to bolster their operational efficiency, sustainability, and competitiveness. This shift, commonly known as Industry 4.0, encompasses the incorporation of digital tools, data analysis, and automation within the realms of manufacturing. In this article, we will delve into the ways in which paper mills are harnessing the potential of Industry 4.0 to attain higher levels of efficiency and address the demands of a contemporary, environmentally-aware society.

The Evolution of Paper Manufacturing

Paper manufacturing has come a long way since its inception in ancient China over two thousand years ago. Initially, paper production was a labor-intensive, manual process, relying on plant fibers and water. Over time, technological advancements led to the adoption of machinery for pulp preparation, papermaking, and printing, significantly improving production efficiency.

However, the traditional paper industry still faces challenges such as high energy consumption, waste generation, and environmental concerns. The industry needed a paradigm shift to address these issues and remain competitive in the 21st century. Enter Industry 4.0.

| Also Read: Paper Coating Technologies: Enhancing Print Quality and Performance |

Industry 4.0: Revolutionizing Paper Manufacturing

Industry 4.0, known as the fourth industrial revolution, is marked by the fusion of digital, physical, and biological technologies. Within the realm of paper manufacturing, this entails the incorporation of state-of-the-art technologies to streamline processes and facilitate the production of environmentally sustainable products.

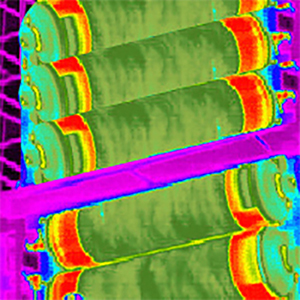

- Smart Sensors and IoT: One of the pillars of Industry 4.0 is the extensive use of smart sensors and the Internet of Things (IoT). These sensors can be installed throughout the paper mill to collect real-time data on various parameters, such as temperature, humidity, pressure, and machine performance. By analyzing this data, operators can make informed decisions to optimize production and prevent equipment failures, reducing downtime.

- Advanced Analytics: Big data and advanced analytics play a crucial role in Industry 4.0. Paper mills use machine learning algorithms to analyze vast datasets generated by sensors. This helps in predictive maintenance, quality control, and energy optimization. For instance, algorithms can predict when a machine component is likely to fail, allowing for timely maintenance, and thus reducing unplanned downtime.

- Automation and Robotics: Automation is another key aspect of Industry 4.0. Robots and automated guided vehicles (AGVs) are used for tasks such as material handling and quality inspection. These machines work efficiently round the clock without fatigue, contributing to consistent product quality and productivity improvements.

- Digital Twins: Paper mills are increasingly adopting digital twins, which are virtual replicas of physical assets and processes. These digital models allow operators to simulate different scenarios and optimize production without disrupting the actual process. It's a powerful tool for process optimization and troubleshooting.

- Energy Efficiency: Sustainability is a top priority for the paper industry. Industry 4.0 technologies help paper mills reduce their environmental footprint by optimizing energy consumption. Smart grids and energy management systems can adjust energy usage in real time, taking into account production demands and the availability of renewable energy sources.

- Supply Chain Integration: Digital transformation also extends to supply chain management. Paper mills are using technology to integrate suppliers, logistics, and customers, creating a more responsive and efficient supply chain. This ensures that raw materials are available when needed and finished products reach customers in a timely manner.

Case Studies: Success Stories

Let's take a look at a couple of real-world examples where Industry 4.0 has made a significant impact on paper mills:

- UPM-Kymmene: This Finnish paper company implemented Industry 4.0 technologies in their paper mills, focusing on predictive maintenance. By analyzing data from sensors and using machine learning algorithms, they reduced maintenance costs by 30% and decreased unplanned downtime by 20%. This resulted in a substantial increase in overall production efficiency.

- Stora Enso: Stora Enso, another significant participant in the paper industry, has enthusiastically adopted digital transformation to elevate its sustainability efforts. Employing IoT sensors and data analytics, they have streamlined their supply chain operations, carefully managing the utilization of raw materials and energy for production. This strategic approach has yielded impressive results, including a noteworthy 20% decrease in energy consumption and a substantial 15% reduction in waste.

Challenges and Future Outlook

While the benefits of Industry 4.0 in paper manufacturing are undeniable, there are challenges to overcome. These include the initial capital investment, cybersecurity concerns, and the need for a skilled workforce capable of managing and utilizing these technologies.

Looking ahead, the future of paper mills lies in continued digital transformation. The integration of artificial intelligence, blockchain for supply chain transparency, and even more advanced robotics will further revolutionize the industry. Sustainability will remain a driving force, with paper mills striving for carbon neutrality and eco-friendly production.

The additional aspects of digital transformation in paper mills

Supply Chain Resilience: Industry 4.0 also plays a pivotal role in enhancing the resilience of paper mills' supply chains. By leveraging real-time data and analytics, these mills can better anticipate disruptions and adjust their operations accordingly. For instance, in the face of unforeseen events such as natural disasters or global supply chain interruptions, digital technologies enable paper manufacturers to swiftly adapt, reroute shipments, and maintain steady production.

| Also Read: Optimizing Energy Efficiency in Paper Mills: Key Strategies for Cost Reduction |

Eco-Friendly Production: The environmental benefits of Industry 4.0 in paper manufacturing cannot be overstated. Digital transformation allows for precise control over resource consumption and emissions. Sustainable forestry practices, combined with advanced technology, ensure that raw materials are sourced responsibly. Furthermore, digital systems help optimize water usage and reduce chemical waste, leading to a significant decrease in the environmental impact of paper production.

Customization and Personalization: Industry 4.0 enables paper mills to offer more tailored products to their customers. Advanced printing and finishing technologies can produce customized packaging, labels, and paper products with intricate designs and variable data. This not only adds value for customers but also opens up new revenue streams for the mills.

Training and Workforce Advancement: With paper mills transitioning into technologically advanced facilities, there arises an increasing need for a highly skilled workforce. Training programs become imperative to equip employees with the essential skills for operating, maintaining, and troubleshooting these intricate systems. Industry 4.0 endeavors frequently encompass investments in workforce development to guarantee that employees can effectively leverage the complete capabilities of these technologies.

Conclusion

In conclusion, within the framework of Industry 4.0, digital transformation is fundamentally reshaping the landscape of the paper manufacturing industry. By leveraging the capabilities of data, automation, and connectivity, paper mills are on a trajectory toward enhanced efficiency, sustainability, and competitiveness. Notable success stories, exemplified by companies like UPM-Kymmene and Stora Enso, underscore the concrete advantages of this transformative journey. As we look ahead, the paper industry is poised for further evolution, driven by the embrace of cutting-edge technologies. These innovations will enable the industry to effectively address the evolving demands of a rapidly changing world while concurrently reducing its environmental footprint.