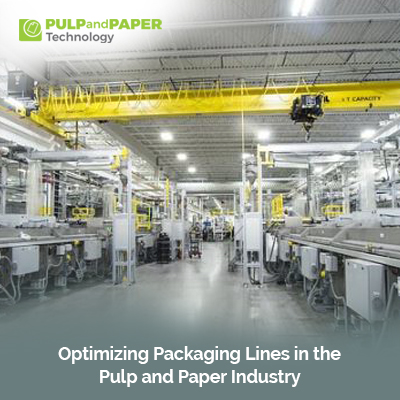

Optimizing Packaging Lines in the Pulp and Paper Industry

Introduction:

In the dynamic landscape of the pulp and paper industry, optimizing packaging lines has emerged as a strategic imperative. The packaging process is not merely about enclosing products; it is a critical link in the supply chain that directly impacts efficiency, cost-effectiveness, and environmental sustainability. This article delves into the multifaceted strategies and technologies employed by industry leaders to optimize packaging lines, thereby driving operational excellence and fostering eco-friendly practices.

1. Streamlining Material Handling: Efficient material handling lies at the core of packaging line optimization. The seamless flow of raw materials, including paperboard, corrugated sheets, and packaging components, is vital for uninterrupted production. Automated material handling systems, such as conveyor belts, robotic arms, and palletizers, play a pivotal role in reducing manual labor, minimizing errors, and enhancing overall productivity. By automating material handling processes, companies can achieve significant cost savings and operational efficiencies.

2. Embracing Innovative Packaging Design: The design of packaging solutions holds immense potential for optimization. Innovative packaging designs that prioritize sustainability, functionality, and cost-effectiveness can revolutionize packaging lines. Lightweight yet durable packaging materials, eco-friendly designs, and space-efficient packaging configurations not only reduce material usage but also lower transportation costs and environmental impact. Moreover, incorporating features like recyclability, biodegradability, and reusability aligns with evolving consumer preferences for sustainable packaging solutions.

| Also Read: Streamlining Sustainability: Packaging Lines Innovations in the Pulp and Paper Industry |

3. Leveraging Advanced Equipment and Technology: The adoption of advanced packaging equipment and technology is a cornerstone of packaging line optimization. High-speed packaging machines, shrink-wrapping systems, labeling machines, and pallet-wrapping machines enhance throughput, accuracy, and consistency in packaging operations. Moreover, investing in energy-efficient equipment and implementing predictive maintenance strategies can significantly reduce downtime, maintenance costs, and resource wastage. By leveraging cutting-edge technology, companies can stay competitive, agile, and responsive to market demands.

4. Implementing Lean Manufacturing Principles: Efficiency gains in packaging lines can be further amplified through the implementation of lean manufacturing principles. Streamlining processes, eliminating non-value-added activities, and optimizing workflow layouts contribute to enhanced productivity and resource utilization. Just-in-time inventory management, standardized work procedures, and continuous improvement initiatives drive operational excellence and waste reduction. By fostering a culture of continuous improvement and operational excellence, companies can achieve sustainable cost reductions and performance improvements in packaging operations.

5. Prioritizing Sustainability and Environmental Stewardship: Sustainability is a central theme in modern packaging line optimization efforts. Companies are increasingly embracing sustainable packaging practices, such as using recycled materials, reducing packaging waste, and implementing eco-friendly packaging solutions. Adhering to sustainable forest management practices, obtaining eco-certifications, and promoting responsible sourcing of raw materials demonstrate a commitment to environmental stewardship. Furthermore, embracing circular economy principles, such as closed-loop recycling and extended producer responsibility, contributes to a more sustainable and circular packaging ecosystem.

6. Harnessing the Power of Data and Analytics: Data-driven decision-making is instrumental in optimizing packaging lines and driving continuous improvement. By harnessing data from sensors, IoT devices, and production systems, companies can gain valuable insights into packaging line performance, efficiency metrics, and quality parameters. Analyzing this data enables proactive maintenance, predictive analytics, and real-time optimization of packaging processes. Leveraging advanced analytics tools and machine learning algorithms empowers companies to identify optimization opportunities, optimize packaging parameters, and enhance overall operational efficiency.

Conclusion:

Optimizing packaging lines in the pulp and paper industry is a multifaceted endeavor that requires a strategic blend of technology adoption, process optimization, sustainability initiatives, and data-driven decision-making. By streamlining material handling, embracing innovative packaging design, leveraging advanced equipment, implementing lean manufacturing principles, prioritizing sustainability, and harnessing the power of data and analytics, companies can achieve significant improvements in efficiency, cost-effectiveness, and environmental sustainability. As the industry continues to evolve, optimizing packaging lines will remain a key focus area for driving operational excellence and meeting the growing demand for sustainable packaging solutions.