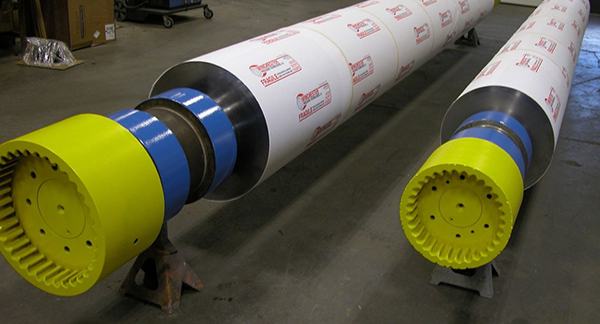

REEL SPOOL

When you need reel spool rolls that you can count on to deliver high performance and longevity, Winchester Precision Technologies offers the solution that suits your needs.

With years of service to the paper, textile, and plastic industries – our experienced team of engineers understands what it takes to make reel spools and rolls of every size offer the best possible performance and ROI.

From the simplest consultation to comprehensive inspection, optimization, repair, and manufacturing – Winchester is the expert on reel spools, paper machine rolls, and more.

Fill out and submit our Roll Specification Tech. form so that we can design and engineer the Reel Spool to match you application. The more information that you can provide the better we will be able to optimize your roll for your process.

How Reel Spool Service Makes a Difference

On a typical paper machine, the reel spools work with the winder drum to wind the paper at the end of the machine then allow for further converting of the paper on other pieces of equipment. This repeated lifting/lowering of spools loaded with paper naturally subjects the equipment to a great deal of stress and wear.

Without regular service, reel spool roll shafts can eventually become bent and damaged. At best a damaged reel spool can cause down time, at worst it can become a critical safety issue as reel spools are lifted in the air with overhead cranes. Increasingly Insurance companies are requiring annual reel spool inspection.