Crystallization Equipment

Crystallization is the separation process by which heat and mass transfer remove solids from a solution in the form of high purity crystalline structures. The two-part process of associated nucleation and crystal growth depends upon the relative rate of each step to control crystal size and population.

Found in a variety of process and waste management operations, crystallization also reduces liquid waste run-off, as the remaining liquid — also purified — can then be cycled back through the system, released into the environment, or passed on to another operation.

Optimizing Crystallization Systems

To achieve optimum efficiency, each crystallization system should be designed on an individual basis, as different types of equipment are more suitable for different applications. This differentiation largely depends on the substances in the mixture, the amount of energy input, and desired crystal size.

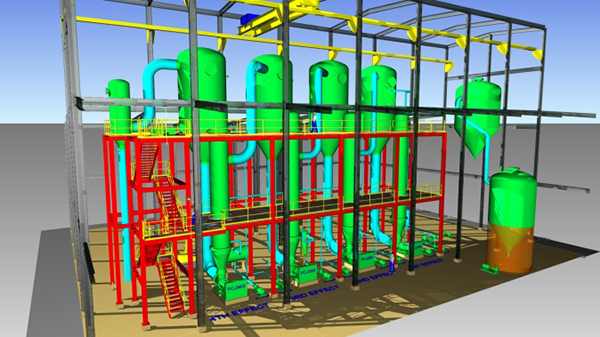

At Thermal Kinetics, our team of engineers, developers, and designers can construct a wide array of custom crystallization equipment to match your unique needs. Whether your crystallizer is a standalone system or part of a larger operation, we can configure it to fit any industry application. From circulating batch models to continuous crystallizers, each of our systems can be adjusted to meet your operational requirements.