High Viscosity In-Line Mixers

High Viscosity In-Line Mixers

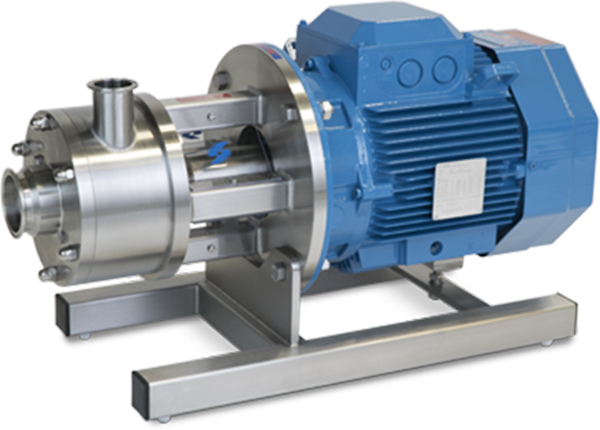

Silverson’s High Viscosity (HV) In-Line Mixers offer exceptional flow rates and the ability to process higher viscosity products.

This is achieved by a unique and innovative “pumping rotor” design which substantially increases the mixer’s capacity when compared to standard In-Line mixers, eliminating the need for an additional feed pump when processing higher viscosity products in the food, pharmaceutical, cosmetic and chemical industries.

Features:

- Ultra sanitary construction - based on the 3-A and EHEDG-Certified UHS mixer range

- Self-pumping

- Aeration free

- No bypassing

- Interchangeable workheads

- Vertical or self-draining tangential outlet

- Designed for Cleaning-In-Place

-

How It Works

Silverson UHS-HV In-Line mixers feature a special rotor design which provides increased capacity, and allows processing of higher viscosities. Operation is as follows:

Stage 1

The high-speed rotation of the specially designed pumping rotor within the precision-machined mixing workhead forces liquid and solid materials into the rotor/stator assembly.

Stage 2

Centrifugal force then drives the materials towards the periphery of the workhead where they are subjected to a milling action in the precision-machined clearance between the ends of the rotor blades and the inner wall of the stator.

Stage 3

This is followed by intense hydraulic shear as the materials are forced, at high velocity, out through the perforations in the stator, then through the machine outlet and along the pipework. At the same time, fresh materials are continually drawn into the workhead, maintaining the mixing and pumping cycle.