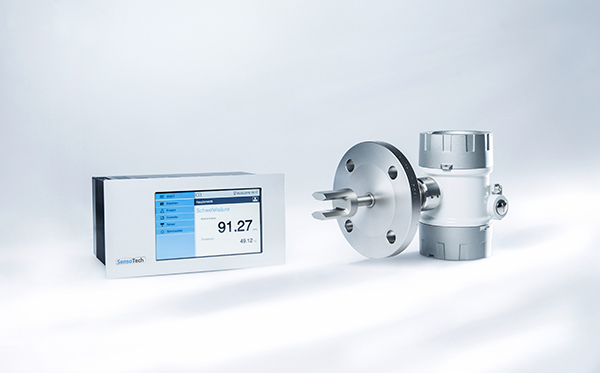

LiquiSonic® measuring systems

The analyzer that sets new standards

Inline Measuring systems for concentration and density analysis of liquids

The LiquiSonic® measuring systems enable inline concentration analysis of liquids. The measurement technology is able to analyze the components of fluid mixtures and can provide information about the concentration or density in real time. The sensors are based on the principle of ultrasonic velocity measurement. They are therefore practically maintenance-free and can reliably provide measured values even under challenging measurement conditions.

The percentage of a specific liquid in a mixture of liquids can thus be determined very easily. Numerous sensor variants and options are available for different applications and installation conditions. We would be pleased to assist you in finding out how the LiquiSonic® measuring system can solve your measuring task.

LiquiSonic® measures inline the concentration or density in almost every kind of liquid. The technology is based on a high-precision measurement and a very fast and stable analytical method. It is independent of conductivity, color and transparency of the process liquids. The measuring results are available online and are updated every second. We offer our customers versions of the system adapted specifically to a wide range of applications in industry and laboratory.

LiquiSonic® consists of up to four sensors and one controller. The devices are digitally connected, what guarantees high, drift-free measurement accuracy and interference-free data transfer at distances of up to 1,000 m (3,280 ft). Interruptions caused by wiring or extensive recalibration when a sensor is exchanged are now things of the past.

The ultrasonic measurement process produces results of exceptional quality when applied in the field. It can deal with extreme processing conditions such as temperatures between -100 °C (-150 °F) and +200 °C (375 °F) and process pressures of a few mbar to 500 bar (7,000 PSI). The stable and maintenance-free nature of LiquiSonic®, as well as the minimal efforts for installation and operation, all pay off in the long run, especially when following a practice of continuous process improvement.

LiquiSonic® allows multiple component measurements to be carried out, such as the independent measurement of scrubbing liquids and the dissolved salt in gas scrubber applications or the alcohol content and residual extract in beer.

We have already prepared complete systems for certain industries; combinations of sensor, controller and user interface are adapted to specific applications:

LiquiSonic® Plato analyzes the original gravity of liquids in breweries,

LiquiSonic® Online Bath Monitor optimizes cleaning and coating baths and

LiquiSonic® Lab is used for laboratory applications.

State-of-the-art configuration software and a broad range of useful accessories are part of our product range.