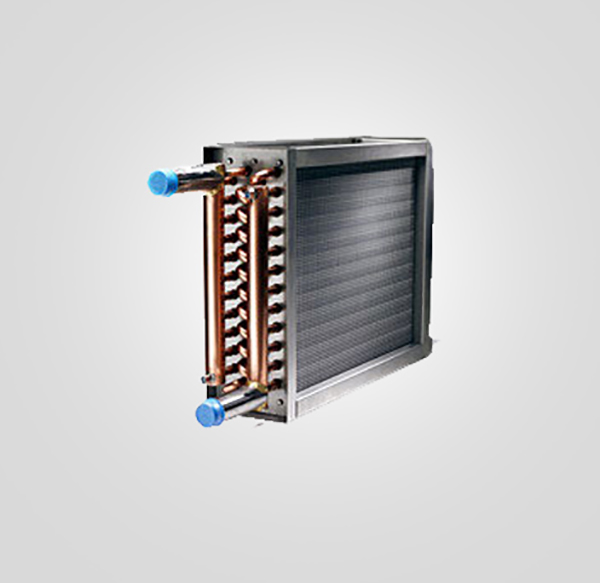

Chilled Water Coils

Chilled Water Coils

Our chilled water coils are made to our exacting standards. We manufacture chilled water coils that are second to none. We make sure that all of our chilled water coils are made with the best materials to the exact configuration required. We will ensure the product is built right and shipped on time, every time.

SPECIFICATIONS

1. Design Pressures & Temperatures

Coils are designed to withstand 250 psi maximum operating pressures and a maximum fluid temperature of 300° F for standard duty copper tube coils. Higher limits are available depending on coil construction and/or materials used.

2. Fin Material

Coils are constructed with plate fin, die-formed aluminum or copper with self spacing collars. Standard aluminum material thickness shall be .0075 +/- 5% and standard copper material thickness shall be .006 +/- 5% unless otherwise specified.

3. Tube Material

All tubing and return bends are manufactured with seamless copper conforming to ASTM B75 and ASTM B251. Tubes are mechanically expanded to form an interference fit with fin collars.

4. Manifold Material

All manifolds are constructed from seamless copper conforming to ASTM B75 and ASTM B251. Each return manifold has a factory installed air vent located at the highest point on the face of the manifold. All core tubes evenly protrude into the inside diameter of the manifold no more than a 1/8”.

5. Brazing

All brazed joints utilize high temperature filler metals. Manifold connections are brazed with filler metal containing at least 5% silver.

6. Casing Material

Casing and tube sheets are manufactured from 16 gauge galvanized steel, meeting ASTMA527 standards. Coils up to ten feet will have a pitched casing toward the condensate connection, a minimum of 1/8” per foot. Coils over ten feet in length should be pitched at time of installation to ensure proper condensate removal.

7. Testing Requirements

Coils are pressurized with a minimum of 350 psi air pressure and completely submerged in water.