Computational Fluid Dynamics

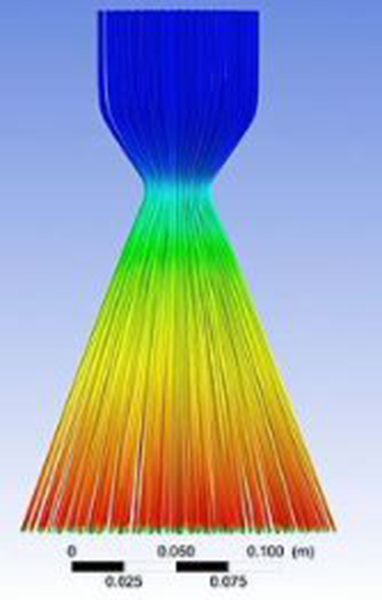

Computational fluid dynamics (CFD) have radically changed the way engineers are able to design more efficient nozzle technology. Referring to the way force, pressure, and distance impact the final outcome of liquid moving through a pipe, CFD data analysis gives us unique insights into what it takes to create highly efficient and complex spray systems, ensuring you have the best options for your business and your applications.

Before we get into the specifics of fluid dynamics, and why it’s so important to your nozzle selection process, let’s dive deeper into the following topics:

What are computational fluid dynamics?

How do they impact nozzle design?

How do we use CFD at Lechler to build the quality nozzles that have made us a top nozzle provider for over 140 years?

Read on to get started!

What is Computational Fluid Dynamics?

“Computational fluid dynamics…is a science that, with the help of digital computers, produces quantitative predictions of fluid-flow phenomena based on the conservation laws (conservation of mass, momentum, and energy) governing fluid motion.”[1]

In layman’s terms, this means that the force, pressure, and distance needed to pump fluid through a straight pipe can be calculated with extreme accuracy. However, what happens when you need more than a traditional straight pipe design? Can fluid dynamics be applied in instances when steam and other hot gases are needed to be pumped through a series of pipes?

There is also the matter of the pipe size and distance the fluid needs to travel to arrive at the intended destination. These types of calculations require special software to discover how fluid and fluid-like substances will flow differently through different systems.

About CFD Software

In a CFD software analysis, the flow of fluid is examined in relation to the physical properties of the fluid, such as velocity, pressure, temperature, density, and viscosity. “To virtually generate an accurate solution for a physical phenomenon associated with fluid flow, those properties have to be considered simultaneously.” [2]

Advantages of Computational Fluid Dynamics Usage

As we mentioned above, if you only need a simple calculation such as a straight stretch of piping, then the flow process and calculation are going to be relatively simple to work out. However, if your spray system design requires even a slight curvature, then you will likely need to use computational fluid dynamic software. Tricky curved pipes, pipes with angles, and ascending flow pipes are situations where computational fluid dynamics is a must.

Our goal with any spray system design is to produce maximum efficiency with minimum resources. One way we do this is by providing you a great selection of nozzles, more control over liquid distribution, water droplet sizes, pumps, compressors, influx, and outflow. This technology (made possible by CFD) puts you in the driver’s seat of your spray system development and saves time and money on the back end by ensuring efficiency.

Other benefits you receive as a result of computational fluid dynamics at work:

You get a front row seat to the identification of spray system optimization potentials.

You are able to view a virtual evaluation of individual measures.

You benefit from risk-free virtual tests