Spur Gear

Spur Gear

Here at Highfield Gears, our team at our Huddersfield-based gear plant have the range of equipment necessary to create and manufacture standard spur gears, or more complex versions, for a whole range of gearboxes and industrial machinery.

Since we were founded in 1927 we have developed our spur gear manufacturing process and now have it at a point where we can create high standards of gears at our gear centre in quick time, all without compromising on length of service life or features.

If you’re a business that uses gearboxes or machinery which feature these types of gears, and you need them repaired or replaced, we can help you. We know the stress, pressure and economic costs that come with a broken gearbox or piece of machinery. The resulting downtime can be catastrophic which is why we offer 24/7 manufacturing options and can work through the night to ensure things are back up and running.

For more information about this service be sure to get in touch with us here at Highfield Gears by phone on 01484531010 or email us at sales@hgi-uk.co.uk. We’ve worked with well-known businesses across the UK and Europe such as Tata Steel and Ineos and are confident we can help you. So, if you’re based in Huddersfield, the surrounding areas of Sheffield, Doncaster, Leeds or further afield in the UK or Europe do not hesitate to get in touch with us today.

What Is A Spur Gear?

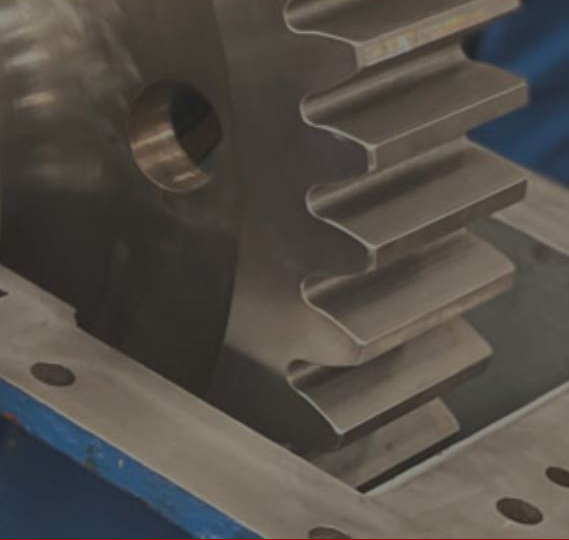

A spur gear is one of the most commonly recognised gear types out there because of its shape, and straight, evenly distributed number of teeth.

Their simplicity and minimal features make them some of the easiest and, crucially, quickest gears to mass-produce. These gear types are known as slow speed gears and are quite noisy due to their design. The loud noises are generated every time a tooth engages another tooth on another gear, unlike a bevel gear or worm gear where the transition between teeth is angled, therefore, smoother. Spur gears are extremely popular and can be used in multiples to create very large gear reductions with great precision. The tooth surfaces are parallel to the axes of the mounted shafts and therefore have no thrust force in the axial direction.

At Highfield Gears, we understand that because of the angle, shape and number of teeth, these gear types need either consistent maintenance or have to be made from strong materials so that they can go the distance for your business. Our gear manufacturing team can either maintain current gears or create new ones to an incredibly high standard so you can rest assured knowing that you’re working with a dynamic turn who can turn their hand to a range of different gear types and shapes.

The Different Types of Spur Gears

Broadly, there are three different types of gears that could be classed as spurs. All of them have their own uses, design, and can handle either a heavy load or light load. In general, these transmission components don't experience high losses due to slippage and, as a result, have high transmission efficiency. Different types of spur gears can be used in sequence to achieve greater reduction ratios, this is called a gear train. These three types have different industrial applications, are varied, and we've been fortunate enough to work on all of these classifications. Read on to learn more about each of them.

External Gears

The external class is the typical spur gear. It is cylindrical and has straight teeth that cut parallel to the rotational axis of the centre of the gear. This external gear is more associated with rolling, as opposed to sliding, and is used in a wide range of industrial applications. The contact occurs along a line parallel to the axis and this can produce less heat and optimum efficiency levels.

Internal Spur Gear

Internal spur gears are another common type of gear that is compact, efficient and transmits motion between parallel shafts that rotate in the same direction. The internal gear is a wheel that has teeth cut on the inside rim, the pinion is housed inside that wheel, allowing it to drive in the same direction at relative speeds which are proportional to the number of teeth.

Rack and Pinion Gears

Rack pinion gears are used to do two things – they either convert rotational speed into linear motion (i.e. a straight line), or they take linear motion into a rotational speed. The rack gear is a straight piece of material with teeth equally spaced out across the line. The pinion is the spur gear and rolls along that rack, with its teeth meshing with the rack. The gear’s diameter determines how fast the rack gear moves as the pinion itself turns. A good example of a rack and pinion gear can be found in the steering system of most cars. The driver turns the wheel, which rotates the gear and moves it along the rack in whatever direction the driver turned the wheel.