HEAT EXCHANGERS

HEAT EXCHANGERS

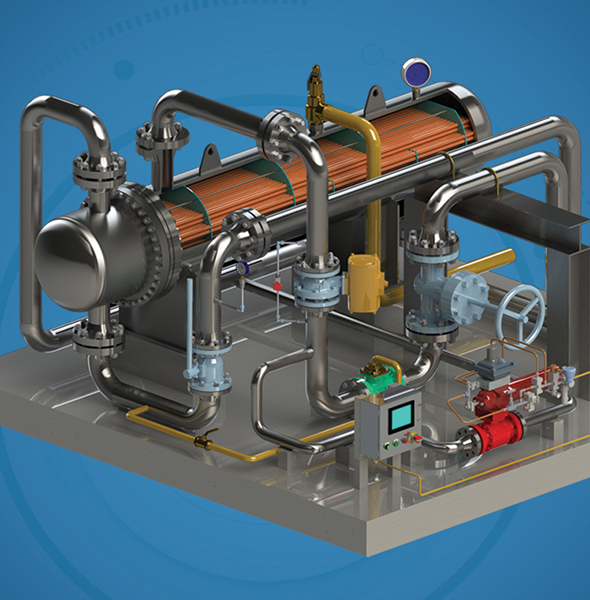

Pioneered in Heat Exchanger Design & Manufacturing

Shell and tube type heat exchangers are highly complicated equipment and critical parts of any industrial plant to provide best thermal performance. Experience and right manufacturing methods play important roles for design and quality. Our fabrication facility is equipped with the latest technology equipment with dedicated fabrication halls for carbon steel and white products; such as stainless steel, aluminum and special alloys, to cater our customers’ needs. We are capable of designing and manufacturing following type of heat exchangers:

- U-tube type heat exchangers

- One pass straight fix-tube heat exchangers

- Two or multiple pass straight fix-tube heat exchangers

- Floating head heat exchangers

Certified Heat Exchangers

ERGIL has been designing and fabricating engineered to order high pressure heat exchangers since 1982. Heat exchangers are a very important part of any process system.

Designing and manufacturing heat exchangers requires certain specialization that has to be accredited by industrial authorities.

In this direction all stations to produce heat exchangers and all materials are chosen and processed according to some certain certifications, also our teams (both white collar and blue collar employee) are trained to catch up required standards.

We carry our specialization to higher standards day by day and our customers, also feedbacks we collect from them are our biggest asset in our journey.

Technology & New Trends

From the conceptual design to commissioning, ERGIL provides unique solutions for shell & tube type heat exchangers.

Keeping customers’ requirements in mind, we follow latest industry standards, regulations and cost effective solutions.

In recent years, ERGIL developed its unique manufacturing technology by cooperating with various machinery manufacturers to maximize welding, tube forming and tube sheet quality efficiency.

Moreover, we invested in the latest technology analysis design softwares in addition to development of our in-house design software.

These helped us to manufacture more complex heat exchangers and optimize product quality.

In-House Design Capabilities

We know the importance of choosing the right design. Our in-house engineering capabilities are blended with our 40 years of heat exchanger project experience.

Our expert team knows what type of design is required for which applications and successfully applies it to major refinery, chemical process plants, and industrial projects.

Our design office is utilising external and internal softwares for thermal, mechanical calculations and FEA analysis requirements.

We are also proud of our pressure vessel design capabilities as per ASME, EN and GOST.