Gearboxes

Gearboxes

The flexible concepts

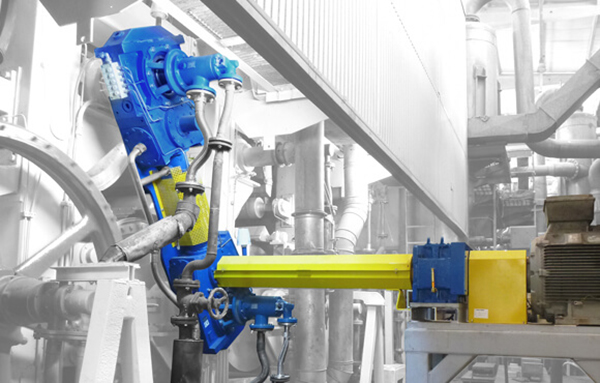

The FlexoGear® gear series from AS has been specially developed for use on drying cylinders of a paper or board machine. In order to be able to absorb the torques, AS has developed a torque support which enables absolutely stress-free operation and makes a connection to the machine frame superfluous. The coupling of the gears allows the operation of up to 4 gears with only one drive motor.

Special gear box for the drying group in a paper machine

The FlexoGear® gear series from AS has been specially developed for use on drying cylinders of a paper or board machine. On the market since 1996, the FlexoGear® gear unit has been installed more than 600 times and has established itself ever since.

Flexible gearbox

The hollow shaft on the FlexoGear® enables it to be mounted directly on the dryer cylinder journal. The FlexoGear® is installed directly on the cylinder journal with shrink discs. Through the use of adapter sleeves, the FlexoGear® can fit almost any cylinder journal. If the existing cylinder journal is too short, it is usually possible to work with journal extensions. This makes the FlexoGear® ideal for modernising the drives on paper-making machines.

The steam needed for the drying process and the condensate that occurs can be directed effortlessly through the hollow shaft.

To assure optimum supply to gear meshing points and bearing locations, oil distributor blocks are installed on every FlexoGear®. From there, oil is directed through pipework to the corresponding locations, supplying them with lubrication and/or cooling oil.

Since all FlexoGear® units are identical in terms of external dimensions, and due to their flexible installation position, it is never any problem to exchange these gearboxes against one another. As a result, only a small number of replacement gearboxes is needed in order to response flexibly, e.g. as a result of maintenance work on the gearbox such as the replacement of wearing parts.

With FlexoGear®, the tendency to break can be significantly reduced and productivity can be greatly improved by reducing downtime. The FlexoGear® can easily reach speeds of up to 1400 metres per minute – of course depending on cylinder circumference and the installed engine power.

The advantages at a glance

FlexoGear®

- Mounting directly on the cylinder journal

- Connection via shrink disc

- Coupling of several gears possible => only one motor per gear group

- Steam and condensate passage

FlexoGear® System

- Only one motor and one frequency converter per system

- Connection via special torque support with three-dimensional movement compensation = no destruction of the torque support

- No connection to the machine frame

- Flexible mounting position and arrangement of the gearboxes

- Direct connection of the gearboxes with maintenance-free all-steel coupling = no intermediate or transfer gearbox