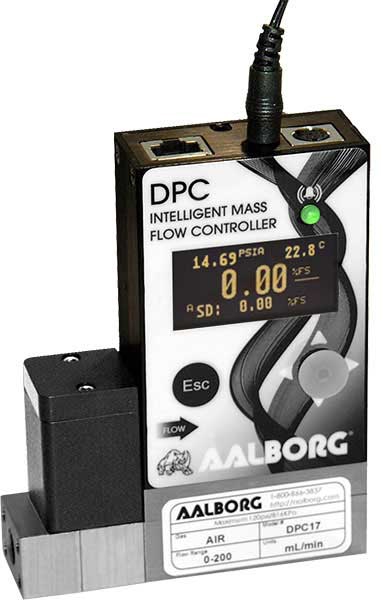

DPC mass flow controller

DPC mass flow controller

Product Summary

Precision Digital Mass Flow Controller with Multi-Gas functionality, Temperature and Pressure

Design Features

- Simultaneously displays Mass Flow, Volumetric Flow, Pressure and Temperature.

- Multi-Gas functionality: support for 90 different gases and gas mixes.

- “User Defined Mixture” functionality allows to create and store up 20 custom gas mixes with up to 5 different gases each.

- Quick (100-150 ms) response time.

- Standard accuracy ± (0.5% RD + 0.2% FS).

- 200 to 1 turn-down ratio.

- Two programmable mass flow rate totalizers.

- High, Low or In Range Alarms with preset action delay for Mass Flow, Temperature and Pressure.

- User programmable mass flow rate Pulse Output (via SSR).

- Extensive Self Diagnostics with status LED or OLED indication.

- All 3 user selectable analog input and output interfaces are standard: 0-5Vdc, 0-10Vdc, 4-20mA.

- Two user selectable digital communication interfaces (RS-232 and RS-485) are standard.

- Optional Modbus RTU network interface with isolated RS485 transceiver.

- User programmable solid state relay with latch option.

- Universal 12-26 Vdc power supply input.

- Local high contrast OLED (optional) graphic display with joystick control.

- Free, easy-to-use configuration and calibration software (RS-232/RS-485)

- Programmable set point table with ramping up/down capability up to 16 steps.

- ** For LOW DIFFERENTIAL PRESSURE models, please contact us **

Description

DPC mass flow controller

** For LOW DIFFERENTIAL PRESSURE models, please contact us **

Aalborg Instruments’ DPC series precision digital mass flow controllers provide accurate and stable control of mass flow rate, of process gases. Inherent simultaneous displays of Mass Flow, Volumetric Flow, Pressure and Temperature parameters promote applications in a variety of industries such as scientific and analytical applications, bioreactors and surface depositions, gas sampling, manufacturing and metrology activities.

DPC precision digital mass flow controllers incorporate multi-gas functionalities allowing users on site to select up to 30 different gases locally via optional OLED/Joystick interface, remotely via the RS232/RS485 interface or optional ModBus RTU interface.

DPC flow controllers support various functions including: user selectable local, analog, digital or program set point control, two programmable flow totalizers, LOW, HIGH or RANGE FLOW, temperature and pressure alarms, automatic zero adjustment (activated via local or communication interface), programmable SSR relay, programmable 0-5 Vdc, 0-10 Vdc or 4-20 mA analog inputs and outputs, user-programmable pulse output (via SSR), and extensive self-diagnostics functionality. AALBORG DPC series differential pressure mass flow controller features totalizers with batch processing mode, ±(0.5% RD + 0.2% FS) standard accuracy, 200:1 turn-down ratio and less than 150 ms response time.

Significant savings are apparent, comparing to the cost of a single DPC embodying these features, with that of acquiring and installing multiple, application-specific devices.

Principles of Operation

Operation of DPC mass flow controllers is based on the measurement of the differential pressure across specially designed restrictor flow elements (RFE). The restrictor flow element is designed to establish laminar flow across the entire range of the instrument’s operation from 0 to 133% of full scale range. A high accuracy and high resolution differential pressure sensor is utilized to measure pressure drop across a laminar flow channel, which is linearly proportional to volumetric flow rate. To convert volumetric flow into mass flow, high accuracy and high resolution absolute pressure and temperature sensors are utilized. Based on data from the sensors and gas properties from the built-in gas database of the instrument, the micro-controller calculates volumetric and mass flow, which along with pressure and temperature parameters are available on the instrument display as well as via digital interfaces RS-232, RS-485 or optional ModBus RTU. In addition, the mass flow reading is accessible via the instrument analog interface which can be set by user to 0-5 Vdc, 0-10 Vdc or 4-20 mA mode.