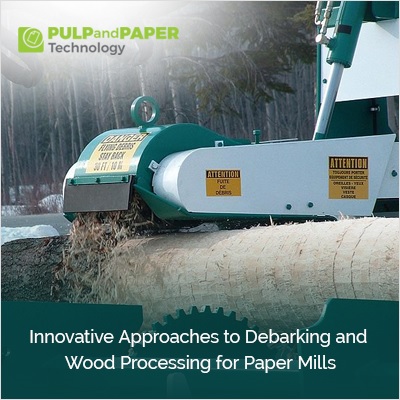

Innovative Approaches to Debarking and Wood Processing for Paper Mills

Today, paper mills are under increasing pressure to meet the growing demand for paper products while minimizing their environmental impact. To achieve this, companies are adopting innovative technologies and strategies that optimize the debarking and wood processing processes.

Traditional methods of debarking and wood processing

In the past, paper mills relied on traditional methods for debarking and wood processing. Manual labor was the primary method, with workers using handheld tools to remove the bark from the logs. This process was time-consuming and labor-intensive, often resulting in inefficiencies and increased production costs. Additionally, the manual debarking process had limited accuracy, leading to a higher risk of wastage.

Wood processing involved manual cutting and shaping techniques that were prone to human error. The lack of precision resulted in irregular dimensions and subpar product quality. This not only affected the overall efficiency of the production process but also resulted in increased material wastage.

Challenges with traditional debarking and wood processing methods

The traditional methods of debarking and wood processing posed several challenges for paper mills. Firstly, the manual labor involved was not only time-consuming but also required a significant workforce. This increased the production costs for paper mills, making it difficult to remain competitive in the market.

Moreover, the lack of precision in the manual debarking process resulted in a higher percentage of wastage. Valuable materials were lost during the inefficient removal of bark, further impacting the profitability of paper mills. Similarly, the manual wood processing techniques led to irregular dimensions and subpar quality, affecting the final product's marketability.

| Also Read: Debarking Techniques: Ensuring Quality and Efficiency in Paper Production |

Innovative approaches to debarking and wood processing

To overcome the challenges posed by traditional methods, paper mills are now adopting innovative approaches to debarking and wood processing. Advanced debarking machines have emerged as a game-changer in the industry. These machines utilize state-of-the-art sensors and automated systems to achieve precise control and optimize the debarking process.

The advanced debarking machines not only remove the bark efficiently but also maximize the recovery of valuable materials. They are equipped with sensors that detect the thickness of the bark, allowing for precise adjustments and minimizing wastage. The automated systems ensure consistent and reliable debarking, leading to improved efficiency and reduced production costs.

Similarly, modern wood processing methods are transforming the industry. Advanced cutting and shaping techniques, coupled with computerized systems, enable paper mills to achieve precise dimensions and impeccable finish. This ensures improved product quality and reduces material wastage, further enhancing the overall efficiency of the production process.

Advanced technologies in debarking and wood processing

The innovative approaches to debarking and wood processing are heavily reliant on advanced technologies. Sensors play a crucial role in optimizing the debarking process by providing real-time data on bark thickness and quality. This data allows for precise adjustments, ensuring efficient removal of bark while minimizing wastage.

Computerized systems are also integrated into the wood processing machines, enabling precise cutting and shaping of logs. These systems utilize algorithms to determine the optimal dimensions and shapes, resulting in superior product quality. Additionally, the computerized systems enable automation, reducing the dependency on manual labor and enhancing overall productivity.

Benefits of innovative debarking and wood processing methods

The adoption of innovative debarking and wood processing methods offers several benefits for paper mills. Firstly, these approaches improve the efficiency of the production process, resulting in higher productivity and reduced costs. The advanced debarking machines and wood processing techniques ensure precise control, minimizing wastage and maximizing material recovery.

Moreover, the utilization of advanced technologies promotes sustainability in the industry. The optimization of debarking and wood processing reduces the environmental impact of paper mills by minimizing material wastage and energy consumption. This not only aligns with the growing demand for sustainable practices but also enhances the reputation of paper mills as responsible manufacturers.

Furthermore, the superior product quality achieved through innovative approaches enhances the marketability of paper products. Precise dimensions, impeccable finish, and consistent quality make the final product more desirable to customers. This, in turn, increases the competitiveness of paper mills in the market, leading to improved profitability.

Best practices for implementing innovative debarking and wood processing methods

Implementing innovative debarking and wood processing methods requires careful planning and execution. Here are some best practices to consider:

- Conduct a thorough assessment of current processes and identify areas for improvement.

- Research and invest in advanced debarking machines and wood processing technologies that align with the specific needs of the paper mill.

- Train employees on the operation and maintenance of the new technologies to ensure optimal utilization.

- Monitor and analyze data from sensors and computerized systems to identify potential optimizations.

- Continuously evaluate and refine the debarking and wood processing methods to adapt to changing market demands and technological advancements.

Future trends in debarking and wood processing for paper mills

The future of debarking and wood processing for paper mills looks promising, with several exciting trends emerging. One such trend is the integration of artificial intelligence (AI) and machine learning (ML) algorithms into debarking and wood processing machines. These technologies have the potential to further enhance efficiency and reduce wastage by continuously learning and optimizing the processes.

Additionally, there is a growing focus on sustainability in the industry. Paper mills are exploring innovative debarking and wood processing approaches that minimize environmental impact, such as utilizing renewable energy sources and implementing circular economy principles.

Furthermore, the adoption of digitalization and connectivity is expected to increase. Paper mills are likely to leverage the power of data analytics and Internet of Things (IoT) technology to achieve real-time monitoring and optimization of debarking and wood processing processes.

Conclusion

Innovative approaches to debarking and wood processing are revolutionizing the paper mill industry. Advanced debarking machines and modern wood processing methods offer improved efficiency, reduced costs, and enhanced product quality. By embracing these innovative approaches, paper mills can meet the growing demand for paper products while minimizing their environmental impact. With the integration of advanced technologies and the adoption of best practices, the future of debarking and wood processing for paper mills looks promising, paving the way for a sustainable and thriving industry.