Efficient Corrugation Systems: Improving Productivity in the Paper Industry

The paper industry has seen remarkable advancements in recent years, especially in corrugated packaging boxes. Corrugated packaging box manufacturers are leveraging double wall corrugated materials and Corrugated Packaging Machinery for productivity enhancement and waste reduction. Digitalization in corrugated packaging and the use of recycled corrugated paper support plastic reduction efforts, improving productivity in paper manufacturing. This includes the production of carton boxes for packing and corrugated paper rolls, contributing to the Corrugated Equipment Market's growth. These innovations ensure efficient and sustainable packaging solutions, driving productivity and sustainability in the industry.

The Advantages of Double Wall Corrugated Packaging

Double wall corrugated packaging is a game-changer for corrugated packaging boxes. It offers superior durability and strength, ideal for heavy-duty applications. This innovation reduces the need for extra layers, leading to productivity enhancement and waste reduction. Corrugated packaging box manufacturers benefit from streamlined production processes and cost-effective solutions. Advanced Corrugated Packaging Machinery ensures high precision and consistency in producing double wall corrugated boxes.

This supports competitiveness in the Corrugated Equipment Market and aligns with plastic reduction goals. Digitalization in corrugated packaging further optimizes material usage and quality control, driving productivity enhancement in paper manufacturing. The versatility of double wall corrugated boxes, including their use in carton boxes for packing, meets diverse industry needs, fostering innovation and demand in the market.

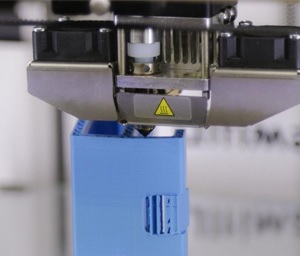

The Role of Corrugated Packaging Machinery

Corrugated Packaging Machinery is crucial for corrugated packaging box manufacturers. Modern machinery optimizes production stages, ensuring productivity enhancement and waste reduction. These advancements in Corrugated Packaging Machinery improve production speed and quality control, meeting demands in the Corrugated Equipment Market. Automation in machinery streamlines processes and handles various materials like double wall corrugated and corrugated paper rolls efficiently. Digitalization in corrugated packaging enhances monitoring and maintenance, supporting continuous productivity enhancement. Machinery flexibility accommodates diverse packaging needs, from carton boxes for packing to large corrugated boxes. Overall, Corrugated Packaging Machinery drives efficiency and sustainability in the packaging industry, shaping its future.

Digitalization in Corrugated Packaging

Digitalization in corrugated packaging has revolutionized the corrugated equipment market. It enables productivity enhancement, waste reduction, and operational efficiency through real-time monitoring and control. Advanced Corrugated Packaging Machinery with sensors and IoT devices ensures optimal production outcomes, reduced downtime, and higher output levels without compromising quality. Digital solutions also facilitate better inventory management, predictive maintenance, and data-driven decision-making. This focus on digitalization aligns with plastic reduction and sustainability goals, driving continuous innovation and improvements in the corrugated packaging industry.

Waste Reduction and Environmental Sustainability

Waste reduction is crucial for corrugated packaging box manufacturers and the corrugated packaging industry. Efficient corrugation systems minimize material wastage, leading to cost savings and a smaller environmental footprint. Recycled corrugated paper supports sustainability by reducing the demand for virgin materials and promoting the circular economy. This shift towards plastic reduction aligns with environmental responsibility and consumer preferences for eco-friendly packaging. Digitalization in corrugated packaging enhances waste reduction efforts by optimizing material usage and production processes, contributing to sustainability objectives and minimizing environmental impact. Efficient corrugation systems also benefit the production of carton boxes for packing and other packaging solutions, further supporting waste reduction and sustainability standards.

Enhancing the Production of Carton Boxes for Packing

Carton boxes for packing are essential in various industries, driving demand for efficient corrugation systems and advanced Corrugated Packaging Machinery. These systems optimize production processes, ensuring productivity enhancement and high-quality output. The scalability of efficient corrugation systems meets dynamic market demands while minimizing material wastage and supporting waste reduction goals. Digitalization in corrugated packaging further enhances carton box production by enabling real-time monitoring and control, optimizing material usage, and promoting sustainability through the use of eco-friendly materials. Overall, the industry's focus on efficiency, quality, and environmental responsibility drives innovation and meets customer expectations.

The Importance of Corrugated Paper Rolls

Corrugated paper rolls are crucial for corrugated packaging box manufacturers and the packaging industry. Efficient production using advanced Corrugated Packaging Machinery ensures productivity enhancement and waste reduction by minimizing material wastage. Quality corrugated paper rolls are essential for producing durable packaging, meeting industry standards, and satisfying customer expectations. Digitalization further improves production processes, enabling real-time monitoring and predictive maintenance for continuous quality improvement and operational efficiency. The use of corrugated paper supports plastic reduction and environmental sustainability, aligning with the industry's focus on eco-friendly materials and responsible packaging solutions.

Strategies for Improving Productivity in the Paper Industry

Improving productivity in the paper industry involves enhancing quality and sustainability while meeting growing market demands. Optimizing Corrugated Packaging Machinery and integrating digitalization revolutionize productivity enhancement efforts. Waste reduction through efficient corrugation systems and recycling initiatives supports environmental sustainability and responsible manufacturing practices. Double wall corrugated materials in corrugated packaging boxes improve strength and reduce the need for additional layers, enhancing productivity and sustainability. Collaborative efforts drive continuous advancements in Corrugated Equipment Market, ensuring competitive edge and environmental responsibility.

Commitment to Waste and Plastic Reduction

The paper industry's commitment to waste reduction and plastic reduction is evident in its adoption of efficient production methods like advanced Corrugated Packaging Machinery and utilization of recycled materials. Efforts towards minimizing material wastage and conserving resources are paramount, including optimizing material usage in corrugation systems. Transitioning to eco-friendly materials and double wall corrugated options further supports sustainability goals and reduces reliance on plastics. Integration of recycled materials and digitalization in corrugated packaging drive continuous improvement in sustainable packaging solutions.

Conclusion: The Future of Efficient Corrugation Systems

In conclusion, the advancements in efficient corrugation systems have revolutionized the paper industry and set the stage for a promising future. Continuous innovations in corrugated packaging machinery and the rise of digitalization in corrugated packaging processes have significantly contributed to productivity enhancement and sustainability within the industry. Corrugated packaging box manufacturers are now better equipped than ever to meet the escalating demands for sustainable and efficient packaging solutions, with a focus on waste reduction and plastic reduction aligning with broader environmental sustainability goals. The double wall corrugated materials and other eco-friendly alternatives play a crucial role in enhancing the strength and durability of corrugated packaging boxes while reducing environmental impact. These advancements, coupled with digitalization in corrugated packaging, enable real-time monitoring, predictive maintenance, and data-driven decision-making, further optimizing production processes and minimizing waste.

Looking ahead, the future of corrugated packaging appears promising, with ongoing technological advancements paving the way for even greater improvements in productivity and sustainability. The industry's ability to adapt to evolving market demands and regulatory standards positions it for continued growth and success in an increasingly competitive Corrugated Equipment Market.