Articles

Different Types Of Industrial Printing Machines

In the industrial set up of the economy, the printing machines are growing in large numbers. Different printing techniques and processes are used by every industry for effective communication. Any machine used in printing ink on the substrate (printing medium) which can be cloth, paper or plastic, is referred to as the printing machinery. By applying pressure to the substrate, the printing machinery transfers the ink on the printing medium resting on an inked platform composed of movable type. The development of industrial printing machines changed a lot of things in the world. It would make transfer and preservation of historical records, scientific findings, and knowledge easy and possible. There's a great advancement in the printing machinery introduced in the market today given the improvement in science and technology. There's a competition in the industry, as many companies are now making printing press. As every company is introducing better features and making an effort to overcome the other competitors, this has led to the introduction of many enhanced features in printing machinery. With the introduction of various features in these types of machinery, printing is now easier to be done than it was in earlier days.

Today, printing machinery is available in many sizes to suit different needs. Bigger sizes of printing machinery are available for heavy-duty printing or big-time printing businesses. You can get small and medium sizes too for small and medium printing businesses. The machinery size determines the volume of printing that will be done in a day, to a greater extent. When compared with small-sized printing machinery, the heavy industrial printing machines can print a lot of things per hour or regularly. There are different types of printing machines for printing on a different medium since different printing machines make use of different printing technology. Each of the below-mentioned printing machinery is meant to serve a particular purpose. You must consider your printing needs or the type of printing that you are doing before you want to buy or order for your printing machine. Several factors such as the size, the type of printing done, the seller, the brand, and others determine the cost.

Types Of Printing Machines

- Digital Printers

- Ink-jet Printers

- Screen Printers

- Embossing Machines

- Flexographic Printing Machine

- Letterpress Printing Machines

- Offset Printers

- Laser printers

- Wireless Printers

- 3D Printers

- Thermographic Printers

- Electrostatic Printing Machine

- Pad Printers

- Rotogravure Printing Machines

A) Digital Printers

The digital printing machines have gained immense popularity for short to medium run jobs requiring high clarity, quality, and fine printing. A vibrant quality image is delivered with these types of printers. By providing cost-effective and fine printing solutions, these affordable and high-performance machines are revolutionizing the printing industry. Because of the on-demand services, digital printing equipment ensures fast turnaround time. Digital printers are ideally suited to publish a small print run of posters and books. They have many advantages over traditional methods. Some include -

- Desktop printing

- Commercial

- Variable data printing

- Fine art

- Print on demand

- Advertising

- Photos

- Architectural design

- Sleeking

B) Ink-Jet Printers

These are a category of industrial printing machines in which printing is done with the help of inkjet technology. In this, a digital image is created by propelling ink droplets onto paper, plastic, or other substrates. These are the most commonly used type of printer, ranging from small inexpensive consumer models to expensive professional machines. They are affordable and easy to use compared to most printers. Ink-jet printers are great image printers and are quick starters. They do not require any warm-up time and are inherently quiet. Generally, they are compact and hence require less space. With all these features, the ink-jet printers are more famous as home printers. One disadvantage with this type of printer is the durability of the print head which is a little less. It's expensive and can dry up, causing not only ink wastage but also blockages within the printer. They are slow to work and hence are not considered suitable for high-volume printing.

C) Screen Printers

These are one of the versatile printing machines that are compatible to work on many surfaces including ceramics, textiles, wood, paper, metal, glass, and plastic. The screen printers can print on substrates of any shape, size, and thickness. They are capable of providing exciting effects that cannot be possible with other printing methods. The reason behind this is the presence of the broad range of dyes and inks which are five in types such as - solvent, water, solvent plastisol, UV curable, and water plastisol. Sharp-edged images are created by making use of stencils. The screen printers are an ideal choice and an economical way of printing when you need to produce nameplates, labels, signs, t-shirts, shirts, and other articles in large volumes.

Moreover, to create large batches of graphics as posters or display stands, the graphics screen printing is used. You can also create full-color prints. The screen printing is also known as serigraphy or silk-screening. It can also be used to print images on DVDs, CDs.

D) Embossing Machines

These types of industrial printing machines are used by the printing industry for fine printing on many products. With the help of these machines, a three-dimensional image or effect is created on different substrates. The embossing can be done on different materials including paper, metals, textiles, etc. They are also used to enhance the look of aluminum foils. To accommodate different materials, the machines are equipped with embossing modes.

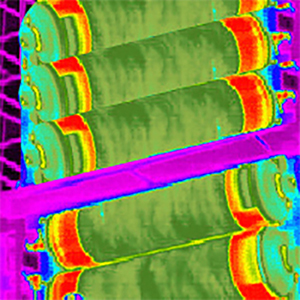

E) Flexographic Machines

Commonly called the modern version of the letterpress. It's also referred to as Flexo, as it was initially used to print onto corrugated cardboard. Flexography printing is used mostly for packaging. These machines produce finer, high quality, and clear impressions on different substrates. Because of the simple operation and easy adaptation for the use of water-based inks, these machines are quite popular. The flexo printing is inexpensive and a simple form of the printing method, to produce an excellent quality impression on several different materials. By using rubber/plastic printing plates, these machines are popularly used for printing on materials including paper, foils, plastic, acetate films. Another advantage of this flexo printing machine is that it has a high-speed printing process and makes use of fast-drying inks. Such printing machines can print on a range of absorbent and non-absorbent materials and can print in continuous patterns.

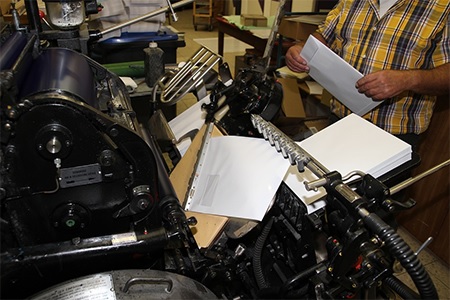

F) Letterpress Printing Machines

Also known as relief or typographic printing machines. They are widely used to make copies of images by repeated direct impression of an inked, raised surface against rolls or sheets of paper. The substances used in letterpress printing are similar to those used in lithography, which includes film developers and fixers, inks and blanket and roller washes. Because of the advent of more efficient and advanced printing presses like the offset printing machine, lithographic press or the flexographic press, the use of letterpress has been on the decline. But, to revive its existence and hold sway even in the 21st century, photopolymer plates have been incorporated which paved the way for letterpress printing.

G) Offset Printers

The offset printing machines have been widely used in various applications. Because of its unparalleled quality to voluminous production and paper costs, it's by far the most dominant form of commercial printing technique, widely in use. Although the machines have a high set up cost, the printing process is comparatively cheaper. Also known as lithographic printing, the machine provides vivid and sharper images and high volume commercial printing, which makes it exceptional from others. Depending on the method used, it can also be known as lithographic or planographic.

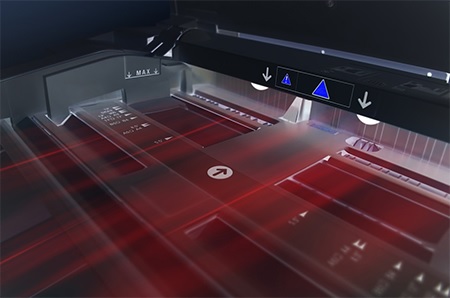

H) Laser Printers

Laser printers are the most common type of printing machine and have remained a popular choice for consumers. There remains a misconception that laser printers use actual lasers to print the paper in some way. But, to clear the air, laser printers use static electricity to print the documents. Due to their ability to produce crisp and rapid printing, laser printers are popular.

I) Wireless Printers

In wireless printers, the data is received by the printer wirelessly, eliminating the need for any type of cables. This implies that the printers are not limited by the length of the cables. There will be no chance that people may trip over the wire. Another advantage is that instead of connecting to just one, many computers can connect to the printer instead, as long as they are connected to the wireless local area network. The user can encrypt the connection with a password, for restricted access to the printer. It all depends on the strong wireless signal, for the printer to be able to access data.

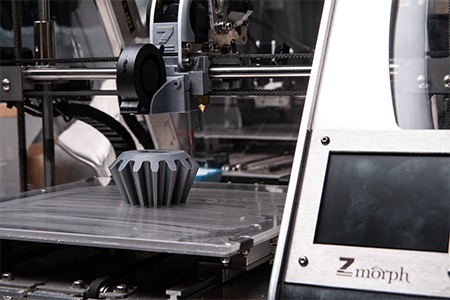

J) 3D Printers

The 3D printer is the latest technology and it opens up many possibilities of printing. 3D printing can print three-dimensional objects, instead of traditionally printing pictures or text on paper. It can produce functional hand tools or any object that can fit in the printer. The ability to duplicate items with the same dimensions is what makes the 3D printing machines so unique. Laser and metallic dust are used by the most advanced 3D printing machines to create 3D objects. We may soon be able to print anything we want, with the advancement in 3D printing technology.

K) Thermographic Printers

This industrial printing machine is widely used in the commercial printing industry. They provide a raised lettering effect, as commonly seen in business cards. Besides, these machines also provide less expensive alternating to embossing, UV coating or stamping.

L) Electrostatic Printing Machines

These types of printing machines use electrostatic forces to form the image in powder or ink directly on the surface to be printed. Because of its high speed and cost-effectiveness, the electrostatic printing machine has become so popular. To print maps and small books and ideally for small scale printing projects, the electrostatic printer is used particularly by publishers and cartographers. A classic quality of the print is constantly produced over a long period without making any changes to the settings of the printers. The electrostatic industrial printing machines that are inexpensive, reliable, and provides excellent resolution and printing quality, are required.

M) Pad Printers

It’s a type of offset printing that provides fast and high clarity printing. One of the most versatile printing technique that is used to print three-dimensional objects. In industrial printing, the pad printer reigns supreme for high quality and fine printing on various materials including rubber, ceramic, metal, and plastic. The quality and printing speed of pad printing machines depends on the thickness of stock/paper, type of inks used and other operating conditions.

N) Rotogravure Printing Machines

It's used for long-run printing with fine, sharper, and clear images. Generally used for high-volume printing of wallpaper, packaging, and gift wraps using fast-drying inks. Although it's not widely used, it still finds it's applications in printing magazines, high-volume advertising print campaigns, and greeting cards.