Articles

Applications Of Adhesives And Chemicals In Paper Industry

Adhesives are designed for specific applications. Apart from playing a role in the adhesion process, the adhesives can be used for varied purposes. Now-a-days, there are synthetic products which have more adhesion power than the natural ones, while earlier plant resins were used as common adhesives. The word 'adhesive' defines substances which tend to stick or adhere to other substances. People, in ancient times, made their glues from whatever they found in the world around them such as fish skins, sugar and animal products boiled in water.

Even though we are much more likely to use artificial adhesives that are made in chemical plant, we still use some of the natural adhesives today. The modern glues, which we get today are nothing but chemical products with terrific names like phenol formaldehyde, cyanoacrylate, ethylene vinyl acetate, and polyvinyl acetate to name a few. For no good reason, many modern adhesives are called synthetic resins as these were one of the first widely used adhesives.

Use Of Adhesives In The Paper Industry

In daily life too, adhesives are used for many functions. It serves its purpose in every small product around us. They can be used to eliminate the effect of self-loosening caused by dynamic loads, as sealing agents, waterproofing, sealing of areas to prevent corrosion and oxidation. Apart from the packaging industry, one of the largest users of adhesives is the paper industry. The adhesives used in paper and packaging can be categorized into two main types -

1) Water-based systems like starch or emulsion adhesives, dextrin's and

2) Hot melts

Among other things, the type of packaging adhesive to use in an individual case depends on the material to be bonded, the end-use demands on the bond and also the production equipment. At times, waterborne adhesives are the better solution and sometimes hot melts are the adhesives of choice. However, the functionality of both the types remains the same, they contain a polymer that is responsible for internal strength or cohesion of the adhesive. By melting the polymer into a liquid form, the desired wet-out and penetration are achieved by dispersing or dissolving the polymer in water. Later on, by removing the water by evaporation or absorption or by cooling the melt, the adhesive is returned to a solid condition. It is a physical process that is responsible for building strength in the glue line in both the cases.

The Role Of Chemicals In Paper Industry

In papermaking, there are about 3000 or so different types of chemicals which can be used in its making. But, in practice, only about 200 individual chemicals are typically used, each satisfying a specific need. Some of the important chemicals used are :

• For the Kraft process - Caustic Soda- sodium sulfide

• Sulfurous acid for the Sulfite process

• Caustic Soda, Anthraquinone for the Soda pulping

• To increase the pH in the pulping process of fibers, caustic soda is added.

• For bleaching of wood pulp - Sodium dithionite, chlorine dioxide, hydrogen peroxide, ozone

• Bleaching additives: sodium silicate

• Sequestering agents: EDTA, DTPA

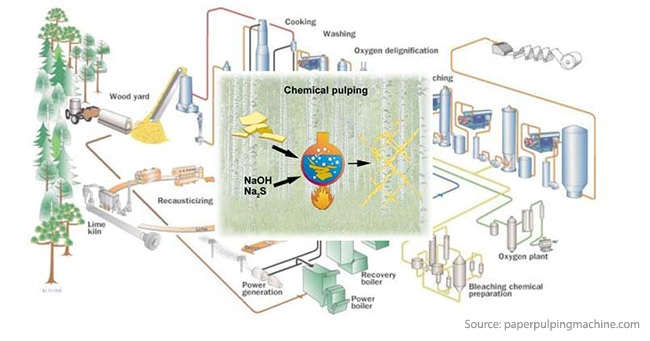

Chemical Pulping

Various chemical reagents as well as heat are used in the chemical pulping process to soften the lignin. It is then dissolved and then mechanically refined to separate the fibers. Practically, two different chemical pulping processes are used. The first is the Kraft pulping also known as sulfate process. About 80% of the world pulp production is processed using this method. Hence, it is currently the dominant technology. Due to several factors, Kraft pulping has become the most commonly used method.

| Also Read: Exploring the Role of Adhesives and Starch in Modern Paper Manufacturing |

Sulphite process is the second process of chemical digestion. An aqueous solution of sulfur dioxide in the presence of alkalis (for e.g. magnesium, ammonium, calcium and sodium) is used in this process. When compared to Kraft pulping, the sulphite process is more efficient, obtains a very light pulp which is easily leached and produces less unpleasant gases. The sulfite technology, has been replaced by the kraft process unfortunately due to high energy consumption, low fiber quality and low recoverability of the chemical raw materials used in the process.

| Also Read: Bio-based Chemicals in Pulp Production: A Sustainable Approach |

These days, the paper, cardboard and carton production without the use of waste paper is unthinkable. One must highlight on the prerequisite to build up steps in obtaining environmentally safe and high-quality adhesives that best fit their applicability domains.