Industrial Uses Of Centrifugal Pumps

One of the most common and popular type of pumps used for transfer of fluids. The centrifugal pumps have a wide range of models depending on the application needs, industry requirements and viscosity. By applying a centrifugal force, water or other fluids are pushed using a rotating impeller. Undoubtedly, these are the perfect choice in delivering liquids from one location to another in numerous industries.

Principle Of A Centrifugal Pump

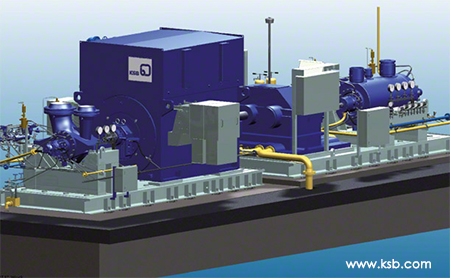

The centrifugal pumps are useful to raise a liquid or induce flow from a low level to high level. Based on a very simple mechanism, the centrifugal pump converts rotational energy to energy in a moving fluid, often from a motor. The energy conversion is mainly due to the two main parts i.e. the impeller and the casing. The rotating part of the pump is the impeller and the airtight passage which surrounds the impeller is the casing part.

How It Works?

The fluid enters into the casing, falls on the impeller blades near the eye of the impeller and is whirled tangentially and radially outward. This process continues until it leaves the impeller into the diffuser part of the casing. The fluid is gaining both pressure and velocity while passing through the impeller.

Industrial Uses Of Centrifugal Pumps

Centrifugal pumps are useful in a wide range of applications in cosmetic, agriculture, wine-making, dairy, mining, petroleum, food-processing, chemical, power generation plants, beverages, pharmaceutical and in other industries. Often used in power plants and oil refineries, they are also the pumps of choice for municipal water applications. Industrially, in cases where a little or no suction lift is required, these centrifugal pumps are used to move the general water supply with pressure.

These pumps can also be used for waste water management, drainage, boiler feed applications, flood protection and irrigation. Apart from this, they also have numerous building applications. They are used as a booster service and for domestic water supplies in buildings for pumping the general water supply. Also used in fire protection sprinkler systems and for heating and cooling applications.

The pumping design of a centrifugal pump makes them useful for sewage and slurries. They have left a major mark in beverage, food and light chemical and dairy industries, they have left a major footprint. They can also be used for drainage and air conditioning systems.

For applications such as petrochemicals, hydrocarbons, food and beverage production, chemicals, paints, cellulose, and sugar refining, these centrifugal pumps are used by the chemical and process industries. In the mining industry, bitumen and minerals from clay and sand are separated by these centrifugal pumps which are used as froth pumps.

Apart from the industrial applications, let's have an in-depth analysis of the various uses of centrifugal pumps.

• To boost pressure

Also serving as booster pumps, these take in pressure from the main water channel and boost it further up ahead. When powered on, they can either run automatically or incessantly from time to time. At a propelled speed, the water from the mainline passes through the impellers on a continuous bases, if driven automatically.

• To supply water for daily utilization

Can be used in applications that do not require much suction lift. Mostly suited to pump water in overhead and pneumatic systems. In order to function effectively, these pumps need to have a suction line with a foot valve, with which we can take a suction lift of up to 15 feet.

• To assist fire protection setups

Centrifugal pumps are used widely by fire fighters in most of the fire protection systems. These pumps can be driven by steam, gasoline or electricity.

• To pump water for domestic applications

Often placed in shallow reservoirs and applications that require a suction lift of not more than 22 feet. Centrifugal pumps can be coupled with gasoline engines and electric motors for its use in deeper wells that require a suction lift of more than 22 feet, to supply water at a uniform rate.

• To assist in hot-water circulation

Usually, a very low head is require to circulate water in closed systems, despite operating at a high static pressure. An efficient stuffing box that is flexible in its mounting and a string casing would make a good centrifugal pump.

• To regulate boiler water

Used to channelize and regulate the water flow, that a boiler is fed with.

• To provide sump drainage

For use in sewage drainage applications, vertical and horizontal centrifugal sump pumps are generally required. A submerged impeller and a pit-mounted motor contains the vertical style, while the latter functions by means of an automated switch.