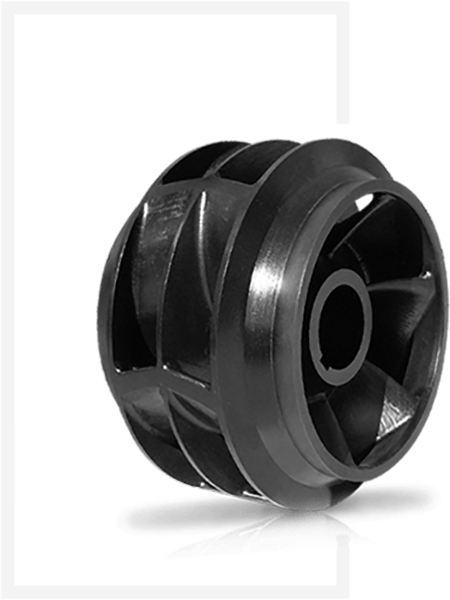

SIMSITE® Impellers & Rings

SIMSITE® Impellers & Rings

The only Impeller that is impervious to salt water corrosion!

Unlike any other Pump Companies, SIMS provides Customers with Impellers, Rings, Sleeves, Guide Bearings, Mechanical seals, Complete Pumps, and many other Pump Parts that outlast, and outperform other products on the market!

For over 100 years, SIMS has been a leader in pump technology! From the invention of the original SIMS Pump Valve to the development of the SIMSITE® Impellers, Pumps, Mechanical Seals, Guide Bearings and Valves, SIMS continues to be a leader in innovative pump solutions for the Marine and Industrial markets. SIMS focuses on innovative solutions for corrosion, erosion, performance and cavitation applications.

SIMSITE® Impellers are superior to all other impellers on the market. SIMSITE® Impellers Never corrode in Sea Water, Wastewater, Sewage, or Chlorinated water applications, and are excellent for many chemical applications. Since 1919, SIMS has focused on complete customer satisfaction with every product manufactured. A unique unconditional customer guarantee is made possible by the highest standards of engineering, manufacture, and customer service.

All SIMSITE® Impellers are 100% machined on the inside as well as the outside from solid blocks of the structural composite, which offers Superior Mechanical Strength, Perfect Balance, Better Performance, Smoother Surfaces, and Longer Life!

Both Impellers ran for 2 years. The SIMSITE® Impeller on the left looks like new! Simsite® is a patented family of superior structural engineered Composite Pumps and Pump Parts approved by the US Navy (and Other Navies around the World), for Navy, Marine, Chemical, Industrial and Waste water applications.

Key Benefits of Using SIMSITE® Impellers, Rings & Pump Parts

- SIMSITE® Impellers and Rings are Corrosion resistant and do not support Electrolysis!

- They NEVER Corrode in in Seawater, Wastewater, Sewage, or Chlorinated Water and are excellent with most Chemicals!

- Simsite® Impellers& Rings are Cavitation & Erosion Resistant!

- Superior to all metallic Pumps in Seawater, Wastewater, Sewage, and Chemical services!

- Operate at Higher Efficiencies.

- Lighter Weight. SIMSITE® Impellers and Rings are 1/6 the weight of bronze, or stainless steel. The high strength to weight ratio of the Simsite® Impeller means a substantial reduction in start-up load, longer bearing and mechanical seal life, and less shaft deflection and vibration!

- Simsite® Impellers have Perfect Balance and they maintain this perfect balance over the life of the pump!

- Eliminate electrolysis. Simsite® is an inert composite which does not conduct electrolysis and therefore saves or prolongs the life of the pump casing even if it is metallic!

- Increase performance, longevity and reliability!

- Simsite® Impellers are 100% precision machined from one piece. They are machined on the inside as well as the outside from solid blocks of the structurally engineered composite, which offers Superior Mechanical Strength, Perfect Balance, Better Performance, Smoother Surfaces and Longer Life!

- Tighter Seals. Simsite® Impellers & Casing Rings will not gall or seize like metallic rings. Therefore, they can operate with a tighter clearance, permitting less leakage through the rings and impeller, which increased pump efficiency. Additionally, Simsite® Casing Rings seal against the casing, which prevents the “wash out” of the casing ring landing areas which is a common maintenance problem with centrifugal pumps.

- Reduces Noise and Vibration. Because of the high efficiency and the precision machined design of the Simsite® Impeller and Pump Casing, and because of the light weight, and noise absorbing characteristics of the structural engineered composite, noise & vibration are reduced in the pump.