MAFLEX

About: Luca Mazzotti - General Manager - Maflex (Italy) & Vice President - Maflex America inc

After completing his studies in mechanical engineering, Mr. Mazzotti started his career as a Service Technician in Fosber America inc. in US. He then joined Maflex (Italy) as technician and then Operations Manager & HR Director. After 10 years he became General Manager succeeding his father, the company founder. He is also in charge as Vice President of the American branch Maflex America Inc.

1. Can you share the key milestones in Maflex's journey since its inception in 1997, highlighting significant developments and achievements?

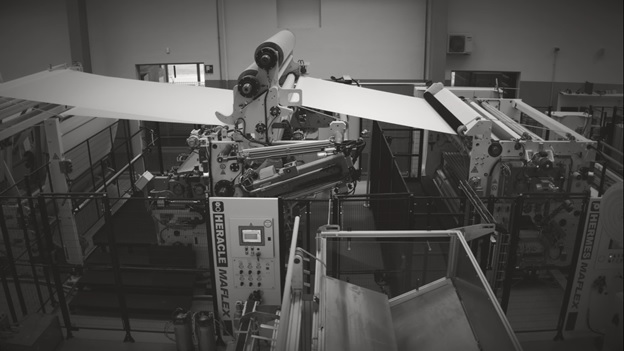

Since its founding in 1997, Maflex has made remarkable progress, consistently focused on meeting customer needs and pursuing excellence in tissue converting machinery. Our clear goal has been to offer innovative, flexible, and high-quality solutions.

Over the years, we have invested in research and development, creating patented technologies that have set us apart in the market. For example, our quick-change embossing roll system, introduced when it seemed everything possible had already been invented, has been a true game changer in the industry.

To meet the needs of customers globally, we have expanded our international presence. In 2012, we opened Maflex America Inc in Green Bay, Wisconsin, establishing crucial partnerships in the United States and Canada.

We continuously collaborate with manufacturers to develop solutions that enhance our existing technologies and address industry challenges. Our next step is a production expansion project to ensure continuous growth.

We are ready for the future, determined to remain a key player in the industry and to continue offering cutting-edge solutions to our customers. We are a company to watch!

2. How does Maflex differentiate itself in the market when it comes to supplying complete lines for converting tissue paper rolls, particularly for both Consumer and AFH markets?

The three key words to answer this question are: FLEXIBILITY, MODULARITY, RELIABILITY. Maflex stands out in the industry by providing complete converting lines for tissue rolls for both the Consumer and AFH (Away From Home) markets, fully customizable to meet customer demands. Our modular philosophy allows us to differentiate each project according to specific needs, ensuring unique and highly reliable solutions.

We recognize that every customer has unique requirements, so we strive to provide tailored solutions. We work closely with them, from design to production, to ensure complete satisfaction.

Our modular solutions offer high performance, efficiency, and reliability, enabling the production of a wide range of high-quality products quickly and efficiently. Additionally, we are committed to delivering top-tier service, supporting customers at every stage of the process, from pre-sales to commissioning and beyond. Our teams of installers, testers, and technicians consist exclusively of highly qualified Maflex personnel, ensuring reliable and prompt technical assistance.

3. What are the core principles that guide Maflex's approach to innovation and product development, especially in terms of addressing evolving customer needs and industry trends?

The heart of Maflex's philosophy is modularity, guiding our approach to innovation and product development. We are an industry benchmark distinguished precisely by this fundamental principle.

Our "made in Italy" technology is a guarantee. Situated in the Tissue Valley of Lucca, we are strategically positioned to effectively serve customers and anticipate industry trends. This is the most significant district globally for the paper industry.

The customer is at the center of everything we do. Before each project, we thoroughly understand their needs and challenges, developing tailored solutions that effectively address their requirements.

We choose partners, suppliers, and components of high quality to ensure that our machinery meets the highest standards of technology, quality, and safety. We believe in the importance of collaboration with suppliers and other stakeholders, as well as working closely with our customers to create value for both parties.

Flexibility and adaptability are fundamental to our approach. This enables us to promptly respond to sudden criticalities, often turning challenges into opportunities for innovation.

4. Could you elaborate on Maflex's research and development efforts, including how feedback from customers and industry insights shape the company's product enhancements and new offerings?

Our Research & Development team is dedicated daily to optimizing machinery, seeking innovative solutions to enhance performance and efficiency. From selecting high-performance components to designing original solutions, we continuously work to overcome challenges and exceed our customers' ambitions.

Our approach is open and customer-oriented, aiming to understand their needs and tailor solutions accordingly. Every challenge becomes an opportunity for us to innovate and improve.

For example, we recently developed a safe and practical solution for loading reels onto overhead unwinders, allowing the customer to work with large reels more efficiently and safely. This is just one of many examples where we have adapted our solutions, demonstrating our utmost commitment to listening in order to achieve all performance goals.

Customer feedback and industry insights are crucial in shaping our research and development work, guiding us towards innovative and tailored solutions that meet market needs. This is what we do very well and it also guides the work of our R&D team. Without listening to customers, we wouldn't have come this far.

5. In what ways does Maflex prioritize safety, efficiency, and design excellence in its machinery, and what impact do these priorities have on customer satisfaction and operational performance?

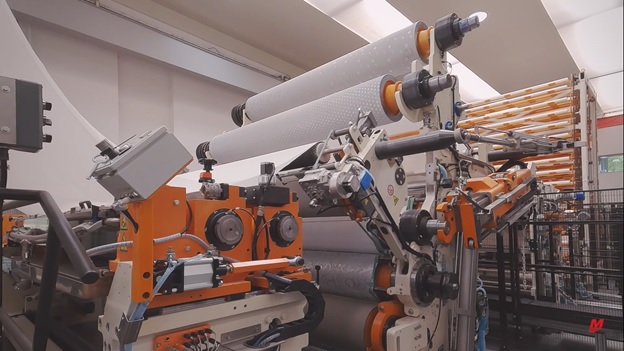

Maflex places great emphasis on production efficiency and workplace safety, two fundamental aspects for the technological research and development of our solutions. These two elements are crucial in the tissue converting sector, where companies are increasingly focused on improving the performance of their production lines.

To address these challenges, Maflex aims to reduce risk factors and ensure maximum operational safety without compromising production efficiency. Our solutions are designed to combine ease of use with high performance and safety, thus contributing to overall operational improvement of production lines.

Furthermore, we are committed to maintaining innovation not only in performance but also in the aesthetics and design of our machinery. Recently, we introduced a new graphic design that adds a touch of modernity and sophistication, emphasizing our identity. This simple and elegant design reflects our concrete, consistent, and reliable corporate style and culture.

6. Can you provide an overview of Maflex's product range related to tissue paper conversion, highlighting key features and benefits that set your solutions apart from competitors?

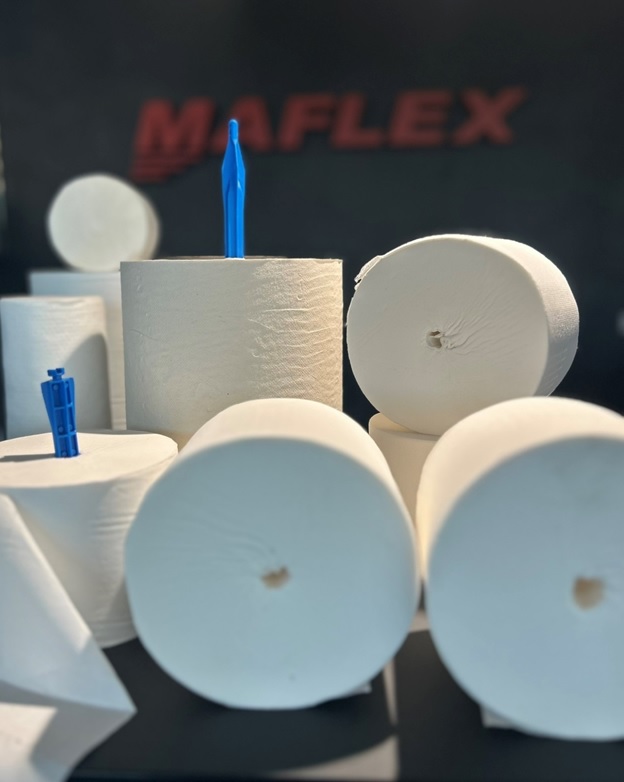

Maflex offers a complete range of solutions for tissue paper converting, covering all the needs of converters. Our offering includes lines for the consumer market and the AFH sector, as well as technologies to add value to the finished product such as printing and embossing, and machinery for the production of rolls with or without cores.

We distinguish ourselves by flexibility, modularity, and reliability, and we believe these are the values on which to build our customers' success.

7. How does Maflex ensure customization and flexibility in its products to meet the diverse needs of customers operating in different segments of the tissue sector?

Thanks to our flexibility and customer-centric approach, we can meet the needs of converters in every part of the world by adapting our solutions to their specific requirements.

Our production lines can manufacture rolls of various lengths, diameters, and densities, with or without cores. Each module of the line is equipped with automation and technologies that enable quick and precise changes, managed directly by the operator through a simple control panel.

8. What strategies does Maflex employ to maintain high levels of product reliability and performance exceeding 600m/min, particularly in today's fast-paced and demanding market environment?

For Maflex, reliability means consistency. We've observed that simply increasing machine speed doesn't always lead to higher productivity. What truly matters is the actual uptime during a production shift. Converters themselves are realizing that by operating at steady speeds, even if slower, they can produce more efficiently and with higher-quality products.

That's why we focus on maximizing the efficiency of our machines, minimizing downtime such as changeovers and maintenance. This allows us to provide real added value in terms of efficiency, leaving more time for transforming tissue rolls into high-quality paper products.

Our approach is pragmatic and realistic: we prefer consistency over frenzy, as it ensures more consistent results in the long run.

9. Could you discuss Maflex's sustainability initiatives and how the company integrates environmental considerations into its operations and product offerings?

Maflex is actively committed to supporting customers in the realm of sustainability and circularity. A crucial aspect is the energy efficiency of our transformation lines. We aim to enhance technologies to make them both productive and sustainable in terms of consumption.

An example is the Maflex Energy Regenerative System (MERS), introduced in 2010. A pioneer at the time, MERS is a system that redefines sustainable energy management practices, allowing for savings of up to 20%. The regeneration units enable MERS to reintegrate unused energy, thereby improving the equipment's carbon footprint. This system helps reduce the overall energy demand in the production facility, optimizing energy efficiency in one of the most demanding sectors in this regard.

10. How does Maflex support its customers post-purchase, including training, technical assistance, and ongoing maintenance services, to ensure optimal performance and longevity of your equipment?

Maflex is committed to providing comprehensive support to its customers post-purchase through a range of targeted services. We offer detailed training on the use of our machinery and timely technical assistance, even remotely, thanks to highly qualified and specialized teams consisting exclusively of in-house staff.

All our facilities are equipped with remote connection systems so that operators never feel alone.

11. What are some recent technological advancements or product innovations from Maflex that have generated significant interest or positive feedback from customers and industry experts?

One of the latest significant innovations introduced to the market is the PEGASO production supervision system, with integrated video, which allows the customer to always have an assistant by their side.

To ensure optimal performance and long-term durability of the machinery, we recommend and provide regular maintenance services. The monitoring system records any type of variation in machine parameters, thus identifying potential component degradation. This allows for proactive intervention and advance planning of replacements during scheduled downtime on the converting lines, thereby avoiding production interruptions.

12. Looking ahead, what are Maflex's strategic priorities and vision for the future, especially in terms of capitalizing on emerging opportunities and addressing challenges in the tissue sector?

Maflex intends to expand its global presence. We are attracted to all markets, especially those that are growing and evolving, whether mature or considered emerging. Our adaptable structure allows us to design machinery specifically tailored for all types of markets.

Furthermore, to support our growth, we are planning to expand our production facility in Lucca, with the doubling of the area within the next two years. This expansion will allow us to increase production capacity and improve operational efficiency.

Our intention is to reaffirm ourselves as a strategic player in the tissue paper sector, offering innovative and high-quality solutions, made in Lucca, supported by a cutting-edge production facility and a continuously growing team of experts.

13. As we wrap up, could you share any upcoming projects, partnerships, or initiatives that Maflex is particularly excited about and that our audience should keep an eye on in the near future?

There's a lot to say indeed. However, we're excited to share one of our latest initiatives: the partnership as a Gold Partner OEM in the PartnerNetwork™ program by Rockwell Automation.

This recognition underscores our commitment to using high-quality components for our machinery. These collaborations strengthen our position in the industry and allow us access to advanced design resources and expertise to best meet our customers' needs.

This commitment to excellence and quality is reflected in our goal to integrate cutting-edge technologies into our production lines, ensuring optimal performance for converters.

This type of partnership represents one of the many initiatives that allow us to explore new and ambitious tissue converting projects. Investing in excellent technology means investing in Maflex's future.

We're excited to advance our vision with high-level partners who, beyond the market, recognize our value and express full confidence in us.