What are the Best Practices for Materials Handling in the Pulp and Paper Industry?

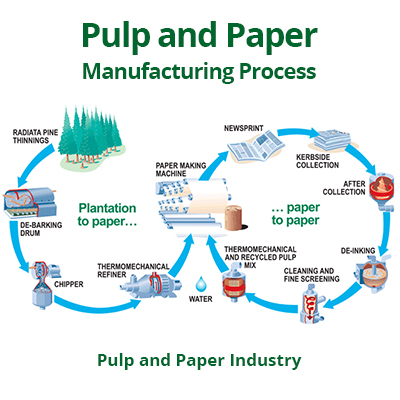

In the fast-paced world of the pulp and paper industry, efficient materials handling is key to maintaining productivity and profitability. From raw materials, such as wood chips and recycled paper, to finished products, like paper rolls and cardboard boxes, the proper management of materials is crucial.

But what are the best practices for materials handling in this industry? How can companies ensure smooth operations and maximize their efficiency?

In this article, we will explore the strategies and techniques that top-performing companies in the pulp and paper industry have implemented to optimize their materials handling processes. We will delve into topics such as warehouse layout and design, equipment selection and maintenance, as well as staff training and safety protocols.

Whether you are a manager looking to improve your materials handling operations or a company executive seeking to enhance overall efficiency, this article will provide valuable insights and practical tips to help you achieve your goals.

Join us as we uncover the best practices for materials handling in the pulp and paper industry and learn how they can positively impact your bottom line.

I. Importance of efficient materials handling in the industry

Efficient materials handling is crucial in the pulp and paper industry for several reasons. Firstly, it directly impacts productivity. Smooth and streamlined materials handling processes ensure that materials are readily available when needed, reducing downtime and allowing for uninterrupted production. This translates to increased output and higher profitability.

Secondly, efficient materials handling improves operational efficiency. By optimizing the movement and storage of materials, companies can minimize waste, eliminate bottlenecks, and reduce overall costs. This not only improves the bottom line but also allows companies to remain competitive in a rapidly changing market.

Lastly, proper materials handling is essential for ensuring product quality. In the pulp and paper industry, materials can be fragile and susceptible to damage. By implementing best practices for handling, companies can minimize product defects and customer complaints, thereby enhancing their reputation and customer satisfaction.

To achieve efficient materials handling, companies need to address common challenges and implement effective strategies. Let's explore some of the key challenges in materials handling for the pulp and paper industry and how they can be overcome.

II. Common challenges in materials handling for pulp and paper

The pulp and paper industry faces several challenges when it comes to materials handling. These challenges include:

Variability of raw materials: The quality and characteristics of raw materials used in the pulp and paper industry can vary significantly. Wood chips from different sources, recycled paper with varying levels of contamination, and other raw materials present unique handling requirements. Companies must develop flexible handling processes to accommodate these variations.

High volumes and heavy loads: The pulp and paper industry deals with large volumes of materials, often in the form of heavy rolls or pallets. Handling such loads can be physically demanding and pose safety risks. Appropriate equipment and proper training are essential to ensure the safe and efficient handling of these materials.

Limited space and complex layouts: Many pulp and paper facilities face space constraints and have complex layouts due to the presence of multiple production lines and storage areas. This can make materials handling challenging, with the risk of congestion and inefficient movement. Careful warehouse layout design and optimization are necessary to overcome these challenges.

Environmental considerations: The pulp and paper industry is increasingly focused on sustainability and environmental stewardship. Materials handling processes must align with these goals, minimizing waste generation, reducing energy consumption, and promoting recycling and reuse. Finding the right balance between efficiency and sustainability is crucial.

Overcoming these challenges requires the implementation of best practices specifically tailored to the pulp and paper industry. Let's explore some of these practices in detail.

III. Best practices for equipment selection in materials handling

The selection of appropriate equipment is a critical aspect of efficient materials handling in the pulp and paper industry. It is essential to choose equipment that is suitable for the specific requirements of the materials being handled, as well as the operating conditions of the facility.

Forklifts and pallet trucks: Forklifts and pallet trucks are commonly used in the pulp and paper industry for the movement of heavy loads. When selecting these types of equipment, factors such as load capacity, maneuverability, and safety features should be considered.

Electric forklifts can be a viable option for indoor operations, as they produce zero emissions and have lower maintenance costs compared to their diesel counterparts.

Conveyors and automated systems: Conveyors and automated systems can significantly improve materials handling efficiency by reducing manual labor and streamlining the movement of materials. They are particularly useful for the transportation of lightweight or fragile materials, such as paper sheets or rolls. When choosing conveyors and automated systems, companies should consider factors such as throughput capacity, versatility, and compatibility with existing processes.

Crane and lifting equipment: In facilities with large-scale operations, cranes and lifting equipment are essential for handling heavy loads, such as paper rolls or machinery. The selection of cranes should take into account factors such as lifting capacity, reach, and safety features. Companies should also prioritize regular maintenance and inspections to ensure the safe and efficient operation of these equipment.

Material handling attachments: Material handling attachments, such as clamps or rotators, can be added to forklifts or cranes to enhance their capabilities. These attachments allow for the secure and efficient handling of specific materials, such as paper rolls or bundles. When selecting material handling attachments, companies should consider factors such as load capacity, adaptability, and ease of use.

By carefully selecting equipment that is appropriate for the specific needs of the pulp and paper industry, companies can improve materials handling efficiency and reduce the risk of accidents or damage to materials. However, equipment selection is just one piece of the puzzle. Ensuring the safety of materials handling operations is equally important.

IV. Safety considerations in materials handling operations

Safety should be a top priority in materials handling operations in the pulp and paper industry. Handling heavy loads, operating machinery, and working in confined spaces can pose significant risks if proper safety protocols are not in place. Here are some key considerations:

Training and education: All personnel involved in materials handling should receive comprehensive training on equipment operation, safe lifting techniques, and hazard identification. Ongoing education and refresher courses are essential to keep employees updated on best practices and safety regulations.

Personal protective equipment (PPE): Adequate PPE should be provided to all personnel involved in materials handling operations. This may include helmets, safety glasses, gloves, and high-visibility vests. The use of PPE should be strictly enforced and regularly monitored.

Safe lifting practices: Proper lifting techniques, such as bending the knees and keeping the back straight, should be emphasized to minimize the risk of musculoskeletal injuries. Employees should be trained on load capacity limits and the correct use of lifting equipment to prevent accidents.

Clear signage and markings: Clear signage and markings should be used to indicate safe routes, load capacity limits, and potential hazards. This helps to prevent accidents and ensures that employees are aware of safety protocols at all times.

Regular equipment inspections: Regular inspections and maintenance of equipment are essential to identify and address any potential safety issues. Companies should have a robust maintenance program in place and document all inspections and repairs.

By prioritizing safety and implementing comprehensive safety protocols, companies can create a culture of safety and minimize the risk of accidents or injuries in materials handling operations.

V. Streamlining materials handling processes for increased productivity

Streamlining materials handling processes is crucial to maximizing productivity and efficiency in the pulp and paper industry. By optimizing the movement and storage of materials, companies can minimize waste, reduce downtime, and improve overall operational performance. Here are some strategies to consider:

Warehouse layout and design: The layout and design of the warehouse play a significant role in materials handling efficiency. Companies should consider factors such as product flow, storage capacity, and accessibility when designing or reconfiguring their warehouses. The use of technologies such as warehouse management systems (WMS) can help optimize storage locations and track inventory in real-time.

Inventory management: Accurate and up-to-date inventory management is essential for efficient materials handling. Companies should implement inventory control systems that provide real-time visibility of stock levels, track material usage, and facilitate timely reordering. This helps to prevent stockouts, reduce excess inventory, and ensure smooth production operations.

Demand forecasting: By accurately forecasting demand, companies can align their materials handling processes with production requirements. This allows for better planning of material flow, reducing the risk of bottlenecks or shortages. Data analysis and predictive modeling can be leveraged to improve demand forecasting accuracy.

Standardized processes and documentation: Standardizing materials handling processes and documenting best practices is essential for consistency and efficiency. By clearly defining procedures and providing training to employees, companies can ensure that materials handling tasks are performed in a uniform and efficient manner.

Continuous improvement and feedback loops: Regular evaluation and improvement of materials handling processes are necessary to identify areas for optimization. Companies should encourage feedback from employees and actively seek out opportunities for innovation and efficiency gains. This can be achieved through structured improvement programs, such as Lean Six Sigma or Kaizen.

By implementing these strategies and constantly seeking ways to improve, companies can streamline their materials handling processes and achieve higher levels of productivity and efficiency.

VI. Automation and technology advancements in materials handling

Automation and technology advancements have revolutionized materials handling in the pulp and paper industry, enabling companies to achieve higher levels of efficiency and productivity. Here are some key advancements to consider:

Automated guided vehicles (AGVs): AGVs are unmanned vehicles that can move materials within a facility without the need for human intervention. They can be programmed to follow predetermined routes, transport materials, and interact with other equipment. AGVs reduce the need for manual labor, improve accuracy, and enhance safety.

Robotics and robotic arms: Robotic systems can be used for various materials handling tasks, including picking, packing, and palletizing. These systems are highly versatile and can be programmed to handle a wide range of materials. Robotics can significantly increase throughput, reduce labor costs, and improve overall operational efficiency.

Smart sensors and IoT: The use of smart sensors and Internet of Things (IoT) technologies can provide real-time data on the condition and location of materials. This data can be used to optimize material flow, monitor equipment performance, and detect potential issues before they become critical. IoT technologies also enable remote monitoring and control of materials handling operations.

Artificial intelligence (AI) and machine learning: AI and machine learning algorithms can analyze large amounts of data to identify patterns, optimize routes, and forecast demand. These technologies can be used to improve inventory management, route optimization, and predictive maintenance. AI-powered systems can also assist in decision-making, suggesting the most efficient materials handling strategies based on real-time data.

Virtual and augmented reality: Virtual and augmented reality technologies can be used for training purposes, allowing employees to simulate materials handling scenarios in a safe and controlled environment. These technologies can improve training effectiveness, enhance employee performance, and reduce the risk of accidents or injuries.

By embracing automation and technology advancements, companies can achieve significant improvements in materials handling efficiency, reduce labor costs, and gain a competitive edge in the industry.

VII. Environmental sustainability in materials handling for pulp and paper

Environmental sustainability is a growing concern in the pulp and paper industry, and materials handling operations play a significant role in achieving sustainability goals. Here are some practices to promote environmental sustainability:

Waste reduction and recycling: Companies should implement waste reduction strategies, such as source reduction and recycling programs, to minimize the amount of waste generated during materials handling operations. This can include recycling paper scraps, reusing packaging materials, and implementing waste segregation systems.

Energy-efficient equipment: The selection of energy-efficient equipment, such as electric forklifts or conveyors, can help reduce energy consumption and lower carbon emissions. Companies should also prioritize regular maintenance and optimization of equipment to ensure optimal energy efficiency.

Optimized transportation routes: Optimizing transportation routes can reduce fuel consumption and carbon emissions. Companies should analyze the most efficient routes for material delivery and implement route optimization software or systems to minimize travel distances and maximize fuel efficiency.

Green packaging solutions: Companies can explore the use of eco-friendly packaging materials, such as biodegradable or recyclable packaging, to reduce the environmental impact of materials handling. This includes using packaging materials made from recycled paper or cardboard and eliminating the use of single-use plastics.

Lifecycle analysis and sustainability reporting: Conducting lifecycle analysis of materials handling processes can help identify areas for improvement and measure the environmental impact of operations. Companies should also consider implementing sustainability reporting frameworks, such as the Global Reporting Initiative (GRI), to transparently communicate their sustainability efforts to stakeholders.

By integrating environmental sustainability into materials handling practices, companies can reduce their carbon footprint, meet regulatory requirements, and enhance their reputation as environmentally responsible organizations.

VIII. Training and education for materials handling professionals

Effective training and education programs are essential for developing skilled and knowledgeable materials-handling professionals in the pulp and paper industry. Here are some key considerations:

Comprehensive onboarding: New employees should receive thorough onboarding that covers safety protocols, equipment operation, and company-specific materials handling processes. This ensures that they have a solid foundation and understand the expectations of their role.

Ongoing training and upskilling: Regular training sessions should be conducted to keep employees updated on new technologies, best practices, and safety regulations. This can be done through in-house training programs, workshops, or external courses.

Cross-training and job rotation: Cross-training employees in different aspects of materials handling can enhance their versatility and adaptability. Job rotation programs can also provide employees with a broader understanding of the overall materials-handling process and improve teamwork and collaboration.

Knowledge sharing and mentorship: Encouraging knowledge sharing and mentorship among experienced and new employees can promote continuous learning and development. Experienced professionals can mentor junior employees, sharing their expertise and guiding them to become proficient materials-handling professionals.

Recognition and rewards: Recognizing and rewarding employees for their achievements and contributions in materials handling can boost morale and motivation. This can be done through performance-based incentives, employee recognition programs, or career advancement opportunities.

By investing in training and education programs, companies can develop a skilled and motivated workforce that is equipped to handle the unique challenges of materials handling in the pulp and paper industry.

Conclusion: The future of materials handling in the pulp and paper industry

In conclusion, efficient materials handling is paramount for the success of companies in the pulp and paper industry. By implementing best practices such as optimizing warehouse layout and design, selecting appropriate equipment, providing comprehensive staff training, and prioritizing safety protocols, companies can streamline their materials handling processes and achieve higher levels of productivity and efficiency. Furthermore, embracing automation, technology advancements, and environmental sustainability practices can further enhance operational performance and contribute to a greener and more sustainable industry. As companies continue to innovate and adapt to evolving market demands, the future of materials handling in the pulp and paper industry looks promising, with opportunities for increased productivity, reduced environmental impact, and enhanced competitiveness.