Ultimate Guide to Papermaking in the Pulp and Paper Industry: Techniques, Processes, and Sustainability

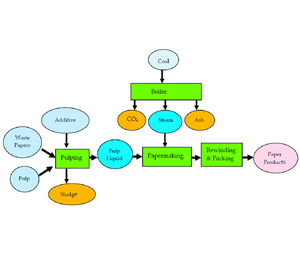

The paper making industry process is a multifaceted journey that starts with the sustainable harvesting of raw materials, mainly softwood and hardwood trees. These logs undergo pulping, either mechanically or chemically, to break down into fibers. Following cleaning and refining to eliminate impurities, the pulp to perfection is mixed with water and formed into sheets on a mesh screen, then pressed to remove excess water. Subsequent stages involve drying, sizing, and coating to enhance the paper's properties, with finishing steps completing the paper making industry process for distribution. Throughout the paper making industry process, sustainability in paper industry practices are paramount, alongside technological advancements shaping the future of this essential sector.

Sustainability in Paper Industry

In the paper making industry process, sustainability in paper industry is a driving force that encompasses a range of initiatives aimed at reducing environmental impact and promoting responsible practices. One key aspect is the emphasis on responsible forestry practices, where trees are harvested sustainably, ensuring that new trees are planted to replace those used for paper making industry process.

Water conservation measures are also critical, with advanced technologies implemented to minimize water usage in the paper making industry process and recycle water wherever possible. Additionally, the industry is actively engaged in recycling programs, encouraging the use of recycled fibers in paper making industry process to reduce the demand for virgin materials and minimize waste. Energy efficiency is another focus, with mills adopting energy-saving technologies and utilizing renewable energy sources to power their operations. Overall, sustainability in paper industry involves a holistic approach that addresses environmental, social, and economic aspects, ensuring a greener and more responsible future for paper making industry process.

| Also Read: The Complete Guide to Paper Machines and Their Installation |

Papermaking Machine

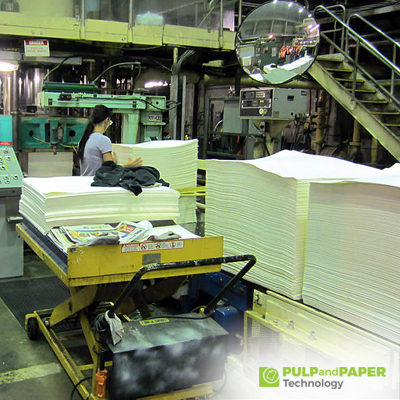

A papermaking machine is a complex system that plays a central role in the paper manufacturing process. This sophisticated equipment combines various components to transform pulp to perfection into high-quality paper products. At its core, a papermaking machine includes a wire section where the pulp to perfection mixture is spread evenly onto a moving mesh screen, allowing water to drain and fibers to form a continuous sheet. The forming section follows, where the sheet is further refined and shaped before entering the press section. In the press section, excess water is removed, and the paper is compacted to enhance strength and smoothness. Subsequently, the dried sheet passes through the drying section, where it is heated and dried to the desired moisture content. Finally, the paper undergoes finishing processes such as calendering and coating to improve surface properties and meet specific quality standards. Papermaking machines are designed with precision and efficiency in mind, incorporating advanced controls and automation to optimize production while ensuring consistent product quality. As a vital component of the paper industry, these machines contribute significantly to the seamless production of various paper grades, from newsprint to specialty papers, catering to diverse market needs.

Pulp to Perfection

In the paper making industry process, the journey from pulp to perfection is a meticulous process that involves several stages to ensure the production of high-quality paper products. It begins with the creation of pulp, where wood fibers are extracted from raw materials such as softwood and hardwood trees. This pulp to perfection undergoes refining and cleaning processes to remove impurities and enhance fiber quality. The refined pulp to perfection is then mixed with water to form a slurry, which is carefully distributed onto a mesh screen in the papermaking machine. Here, water drains away, and fibers interlock to form a continuous sheet, marking the initial step towards perfection. The sheet then moves through pressing and drying sections to remove excess moisture and strengthen its structure. Throughout these stages, precise controls and monitoring ensure that the paper maintains optimal characteristics, including smoothness, strength, and uniformity. Finally, the paper undergoes finishing touches such as sizing, coating, and calendaring, further enhancing its surface properties and overall quality. The journey from pulp to perfection exemplifies the paper industry's commitment to excellence, where every step is taken with precision to deliver papers that meet stringent standards and customer expectations.

Papermaking in Science Technology

Papermaking in science technology represents a dynamic field that integrates cutting-edge advancements to enhance efficiency, quality, and sustainability in paper industry. One key area of innovation is in the development of advanced papermaking machines equipped with state-of-the-art sensors, controls, and automation systems. These technologies enable precise monitoring and adjustment of variables such as pulp to perfection consistency, water content, and drying conditions, optimizing the paper production process for improved productivity and resource utilization.

Furthermore, scientific research plays a vital role in exploring novel materials and additives that enhance paper properties, such as strength, brightness, and printability. Nanotechnology, for instance, has opened new avenues for creating nano-sized additives that enhance paper strength and reduce environmental impact. In terms of sustainability in paper industry, science technology are driving forces behind eco-friendly practices in papermaking. Efforts are underway to develop sustainable alternatives to traditional pulping methods, such as using enzymes or bio-based chemicals to reduce energy consumption and chemical waste. Moreover, digitalization and data analytics are transforming papermaking operations through real-time monitoring, predictive maintenance, and optimization of production parameters. This integration of science technology not only improves operational efficiency but also enables the paper industry to adapt to changing market demands and environmental regulations. In essence, papermaking in science technology represents a continuous journey of innovation, where research, experimentation, and technological advancements converge to shape a more sustainable and efficient paper industry.

Basics of Paper Manufacturing

The basics of paper manufacturing encompass fundamental processes that are essential for transforming raw materials into usable paper products. The journey in basics of paper manufacturing starts with the selection of suitable raw materials, typically wood fibers obtained from softwood and hardwood trees. These fibers undergo pulping, where they are broken down into a pulp mixture. Pulping can be done mechanically, involving grinding and refining, or chemically, using chemicals to dissolve lignin and separate fibers.

Once pulping is complete, the pulp is cleaned to remove impurities such as bark, dirt, and residual chemicals. The cleaned pulp then goes through further basics of paper manufacturing, being mixed with water to create a pulp slurry, which is fed into the papermaking machine. In the machine, the pulp slurry is spread evenly onto a moving mesh screen, allowing water to drain and fibers to bond, forming a continuous sheet.

The sheet then passes through press rollers to remove excess water and compact the fibers, followed by drying to further reduce moisture content. Additional basics of paper manufacturing such as sizing, coating, and calendaring may be applied to enhance the paper's properties, such as smoothness, printability, and durability.

Throughout these basics of paper manufacturing, precise controls, quality checks, and environmental considerations play crucial roles in ensuring the final paper meets desired standards. The basics of paper manufacturing highlight the intricate balance between raw materials, processes, and technology to produce a wide range of paper products used in everyday applications.

Production of pulp and paper

The production of pulp and paper is a complex and vital process that begins with the sustainable harvesting of raw materials, primarily softwood and hardwood trees. These logs undergo pulping, which can be either mechanical or chemical, to break down into fibers. Following cleaning and refining to remove impurities, the production of pulp and paper involves mixing the refined pulp with water and forming it into sheets on a mesh screen. These sheets are then pressed to remove excess water, followed by drying, sizing, and coating processes to enhance the paper's properties.

Throughout the production of pulp and paper process, sustainability practices are crucial.

Responsible forestry practices ensure that trees are harvested sustainably, with new trees planted to replace those used. Water conservation measures, including advanced technologies for minimizing water usage and recycling, are integral to sustainable production of pulp and paper. Recycling programs also play a significant role, encouraging the use of recycled fibers to reduce the demand for virgin materials and minimize waste. Energy efficiency is another focus, with mills adopting energy-saving technologies and renewable energy sources.

A papermaking machine is a central component in the production of pulp and paper, combining various elements to transform pulp into high-quality paper products. From the wire section where the pulp mixture is evenly spread onto a mesh screen to the pressing, drying, and finishing stages, every step contributes to the production of pulp and paper. The journey from pulp to paper exemplifies the industry's commitment to excellence and sustainability.

Innovations in the production of pulp and paper include advanced machines equipped with sensors, controls, and automation systems. These technologies optimize production processes, improve resource utilization, and reduce environmental impact. Scientific research also contributes to enhancing paper properties and developing eco-friendly practices in the production of pulp and paper.

Efforts in the production of pulp and paper industry are directed towards continuous improvement, with a focus on efficiency, quality, and sustainability. The production of pulp and paper is not just a process but a journey of innovation and responsibility towards a greener future.

Process of paper production

The process of paper production is a complex yet meticulously structured series of operations that starts with the sustainable sourcing of raw materials, primarily softwood and hardwood trees. These logs undergo pulping, which can be achieved through mechanical or chemical methods, breaking down the wood fibers into a fibrous mass. Subsequent refining processes remove impurities and enhance the quality of the pulp.

Once refined, the process of paper production involves mixing the pulp with water to form a slurry, which is then spread evenly onto a mesh screen. This step, known as the forming process, allows water to drain, leaving behind a continuous sheet of wet paper. The sheet then passes through pressing rollers to remove excess water, followed by drying to achieve the desired moisture content.

After drying, the process of paper production enters the sizing stage, where chemicals are applied to enhance the paper's strength, durability, and resistance to water. Coating may also be applied to improve printability and provide a smooth surface finish. Finally, the paper is wound into rolls or cut into sheets, ready for distribution and use.

Throughout the process of paper production, sustainability is a key consideration. Responsible forestry practices ensure the replenishment of harvested trees, contributing to forest conservation and biodiversity. Water usage is optimized through recycling and efficient management systems, reducing environmental impact. Recycling programs further support sustainability by utilizing recycled fibers in paper production, reducing the demand for virgin materials and minimizing waste.

Technology plays a crucial role in modern processes of paper production. Advanced machinery, automated controls, and digital monitoring systems enhance efficiency, quality control, and resource utilization. Research and development efforts continue to drive innovation, exploring new materials, processes, and eco-friendly alternatives to traditional methods.

In conclusion, the process of paper production encompasses a series of interlinked stages, from raw material sourcing to final product finishing. Sustainability, technological advancements, and continuous improvement are central themes shaping the modern paper manufacturing industry.

FAQ

What is the papermaking process?

The papermaking process involves several steps. Raw materials such as wood pulp or recycled paper are transformed into pulp through the pulping process. The pulp is then fed into paper machines, where it is formed, pressed, and dried to create sheets of paper.

What raw materials are used in papermaking?

Papermaking requires various raw materials, including fiber sources like wood pulp and recycled paper. These materials provide the necessary fibers to create the paper. Additionally, additives like chemicals and dyes may be used to enhance the characteristics of the paper.

What is the significance of the paper making industry?

The paper making industry plays a crucial role in society. It provides essential products such as paper for printing, packaging, and writing. Moreover, paper products are widely used in sectors like education, communication, and commerce, making the industry vital for economic growth.

How is fiber separated from raw materials in the pulping process?

The pulping process involves separating fibers from the raw materials. This can be done through chemical pulping or mechanical pulping. Chemical pulping uses chemicals to break down the raw materials and separate the fibers, while mechanical pulping physically grinds the raw materials to disentangle the fibers.

What are the finishing and coating techniques employed in the papermaking industry?

Paper finishing and coating techniques include processes like calendering and surface treatments. Calendering involves passing the paper through pressure rollers to improve its smoothness and gloss. Surface treatments, such as coating with additives or applying special finishes, enhance the paper's properties for specific purposes.

How does the papermaking industry address environmental sustainability?

The papermaking industry recognizes the importance of environmental sustainability. It adopts eco-friendly practices like using recycled paper, implementing water management systems to conserve resources, and improving energy efficiency in production processes. These efforts aim to reduce the ecological impact of the industry.

What are the advancements in papermaking technology?

The papermaking industry has witnessed significant advancements in technology. Automation has streamlined production processes, increasing efficiency and reducing manual labor. Digitalization has enabled real-time monitoring and data analysis to optimize operations. Other innovations include the development of specialty papers and environmentally friendly production methods.

What are the challenges faced by the paper making industry?

The paper making industry faces challenges such as digitalization, which requires adapting to changing technological trends. Additionally, market demands and competition pose challenges to the sustainability in paper industry and profitability. Adopting innovative practices and embracing dynamic market trends are crucial for success.

What are the future trends in the paper making industry?

The paper making industry is expected to continue embracing digitalization and automation to enhance efficiency and productivity. Additionally, the industry will focus on catering to evolving market demands, such as sustainable packaging and specialty papers. Innovations in materials and production techniques will drive future trends.

What does this guide provide about the paper making industry?

This guide offers a comprehensive understanding of the paper making industry, including its techniques, processes, and the significance of sustainability in paper industry. It covers topics such as raw materials, the pulping process, paper making industry techniques, environmental sustainability, technological advancements, industry challenges, and future trends.