Types of Paper Board Making Machines

Market Overview

The increased awareness about non-biodegradable materials, its adverse effects on the environment, and the adoption of eco-friendly materials have contributed immensely to the growth of global paper board industry. The global paperboard packaging market is expected to exceed more than US$ 238.50 billion by 2024 and will grow at a CAGR of more than 3% in the given forecast period.

The latest report released by IBIS world for the year 2019 in the month of June stated that the total revenue generated by the paper board was close to USD $ 333 billion. This significantly contributed to the 1.3% increased business in the global paper industry.

Europe and North America are going to be the key players in the paper board manufacturing market during the forecast period. And the large supply of paper and pulp from countries like Germany, Sweden, Italy and Finland are expected to contribute significantly to the growth of the paper board packaging market. Among all, Germany is likely to lead all the countries in the market, says the logistics.

Top paper board making machines

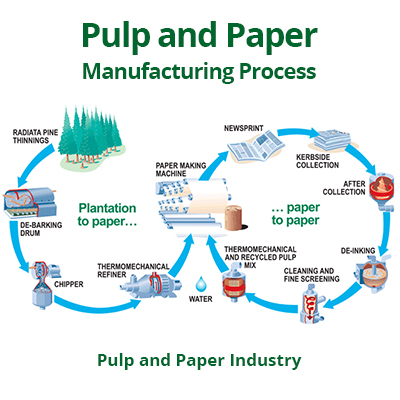

With paper board making industry providing a stable market in the global paper world, it has been grabbing the attention of stakeholders to invest in. Based on the type of industry of manufacturing, paper board machines can be classified under two categories. They are

1. Based on grade

2. Based on end-user

3. Based on product type

| Also Read: The Complete Guide to Paper Machines and Their Installation |

Grade category includes paper board products like folding boxboard (FBB), white line chipboard (WLC), solid bleached sulfate (SBS), coated unbleached kraft paper board (CUK), label paper, and other products like glassine and greaseproof paper, parchment paper, filter paper.

Coming to end-user products, the category includes food and beverages, healthcare, personal and home care, manufacturing, and other products relating to construction, education and stationery.

And in the last category, the products include flexible paper packaging, corrugated box, and boxboard.

Some of the top paper board machines which have been creating a sensation for production of the above-mentioned paper board materials include

1. Automatic paper board making machines sizes ranging between 42,52,62 and 72 inches.

2. L type edge paper board making machine

3. Paper Corrugated board making plant

4. China kraft corrugated paper fluting paper board machine

5. Automatic corrugated paper board vacuum type single facer machine

With China accounting highest for the manufacture of paper-related products, with 99.3 million tonnes of paper and pulp and production, it also deals with the manufacture of best paper board machines across the globe, to match the needs of its market.

The biggest advantage of referring online websites for buying paper board machines is, that there are online representatives from available who can help you in striking the best deal for your product. You can also request them, to help you to select the best machine for your unit, by stating your requirements.

This means it would not only save your time but also your expenses for hiring an expert to get the best selection done for your unit.

Trends in the paper board industry

The food and beverage industry forms the largest consumption sector for the paper board packaging market, as it accounts for more than half of the global market share. With growing competition for different products in the market, and the younger generation opting for better and branded packaged products, there has been a steep rise in the paper board industry globally.

The Flexible Packaging Association in a recent report stated that the beverage sector in the United States had alone accounted for nearly 50% of the packaging market. It further stated, about 30% of the Americans order food twice a week, and this is expected to grow at 3% in the coming years.

On the other hand, countries like India, China, Japan is further fuelling the demand, owing to the increase in the size of the market. However, it should be noted that, in countries like China and India, the demand for food and beverages is always on a higher side, which has been propelling the paper board market to increase annually.

Global scope and challenges of paper board market

The major driving factors as for paper board industry as suggested by reports includes the growth in e-commerce sales and the increased demand for folded cartoon packaging.

It is predicted that almost two-thirds of the population will be living in cities, in the coming years. There has been a steep increase in the migration of rural population to cities, which is certainly going to increase the global demand consumption patterns of packaged food.

Asia Pacific to have the largest paper board industry

It is also to be noted that, paper packaging demand has been growing at a rate of 6.5% since 2008 in the Asia Pacific region. The increased number of manufacturing plants all over the region, coupled with growing demands for paper board packaged products and transit packaging sector in Asia Pacific has contributed tremendously for the growth of paper board packaged products.

Not only this, the logistics sector show an escalating rate of exports as corrugated boxes is expected to dominate the paper board industry in this region. Strong growth of paper board packaging needs in FMCG and cosmetics sector is going to play an important role in the development of this industry in Asia Pacific region. Thus, attracting investors from all over the world to develop the paper board industry into the most lucrative market.