Articles

Top 5 Methods In Minimizing Costs Of Pulp And Paper Production Industry

Ways to optimize cost in paper and pulp production

With paper and pulp industry forming an integral part of the world's growing economy, there has been a steep rise in the demand for products related to paper and pulp industry. To match the competitive needs, the manufacturers in paper and pulp industry, have been discovering ways to reduce the cost of paper and pulp production with qualitative output, within limited resources.

The below-listed points will not only allow you to have a fair understanding of the techniques related to paper and pulp production but would also help you get things done within a cost-effective budget:

1. Embarking on renewable sources of energy

The average specific energy used for the production of paper (per tonne) is around 52GJ. There is a total of eight sectors which operate in a paper and pulp mill, out which the three sectors which consume the maximum electricity units include Perform, Archive, and Trade (PAT) mechanism.

The total energy used during paper and pulp production is around 1.4 million MTOE.

This not only increases the total cost of paper production but would also keep you on heels during production time, as the cut in the supply of power will destroy your complete production. Not only this, but it would also keep the life of workers working within the unit as risk, as the breakdown of pulp emits a lot of harmful gases.

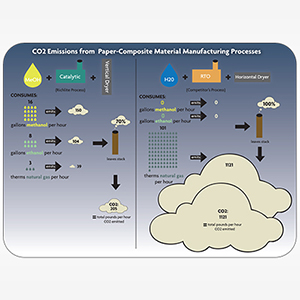

The use of renewable sources of energy like biomass and solar plants will not only save the production time but would also contribute to lower carbon dioxide emissions and reduced climate impact from the pulp and paper industry.

2. Use of technologies for error-free production

There is a significant opportunity for the sector for cost reduction in paper and pulp production with the application of smart technologies. The application of smart technologies helps the paper and pulp manufacturers to bridge the gap, that traditionally existed between information technology (IT) and operations technology (OT).

The manufacturers of paper and pulp industry by applying data analytics, artificial intelligence and machine learning to the industry data which is available, the manufacturers can transform the resulting improved visibility into business insights to improve operational efficiency all throughout the production chain. One such application which connects the IT and OT operations is ABB ability, the digital platform which is a part of smart technology.

3. Use of recycled products for paper and pulp production

The advantages of using recycled products for paper and pulp production is one of the effective ways of cost reduction in paper and pulp production. The advantages include saving energy, water and landfill space. It should be noted that paper recycling reduces greenhouse gas emissions and recycled fibre is a sustainable and cost-effective resource for new paper products.

4. Planning the resources in advance

Planning resources for the manufacturing process in paper and pulp industry plays an important role in cost reduction in pulp and paper production. At an average to produce one tonne of printing paper, 24 trees are required with the combination of softwoods and hardwoods. These trees should be 40 feet tall and should have a diameter of 6 to 8 inches.

Based on the productivity required of particular paper industry, one can plan out the resources in advance. Purchasing the resources at a time for six months or a year will help the manufacturer to get deals at wholesale rates, which can reduce the budget burden from their minds.

5. Preventative Maintenance (PM)

Survey reports say about 60 to 80% of all equipment malfunctions on quality control systems in paper and pulp mill are caused due to incorrect or lack of maintenance. This would not only incur additional cost for production but would destroy the production time.

Pulp and paper mill are exposed to harsh environments, that produces a large amount of dust and extreme heat. Preventative maintenance will eliminate and reduce the effects of heat and dust on machinery and equipment, which play a critical role in affecting the performance of these structures.

Paper and pulp industry on a global platform