The Evolution of Pulp and Paper Manufacturing: From Traditional to Sustainable

Introduction:

Pulp and paper manufacturing has transformed significantly over the years, shifting from resource-intensive methods to more sustainable practices. This evolution stems from an increased awareness of the industry's environmental impact and the pressing need for responsible resource management. In this article, we will provide an overview of this journey, highlighting key milestones in the sector's progress towards sustainability.

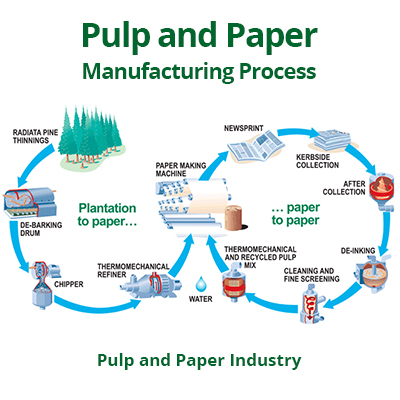

I. Traditional Pulp and Paper Manufacturing: Traditional pulp and paper production dates back centuries, employing manual labor and basic machinery. However, this industry's methods heavily relied on wood as the primary raw material, contributing to deforestation and environmental degradation. The 18th-century Industrial Revolution marked a turning point with the introduction of steam power and mechanization. Although these innovations improved efficiency, they exacerbated environmental concerns by increasing wood demand and energy consumption.

II. Environmental Concerns and Regulatory Measures:

A. Deforestation and Habitat Loss: Historically, the industry's rampant logging practices led to extensive deforestation and the loss of biodiversity. This raised alarm bells about the destruction of natural habitats and its impact on endangered species.

B. Pollution and Waste: The pulp and paper sector was notorious for water pollution due to the release of harmful chemicals into rivers and streams during the pulping process. Additionally, emissions of sulfur dioxide and other pollutants pose serious air pollution issues.

| Also Read: Paper Industry Evolution: Navigating Sustainability, Tech, and Market Shifts |

C. Government Regulations: Governments worldwide recognize the need for environmental regulations to control emissions, reduce waste, and promote sustainable forestry practices. These regulations played a pivotal role in driving the industry towards more sustainable practices.

| Also Read: Quality Control in Paper Manufacturing: From Fiber to Finished Product |

III. Sustainable Pulp and Paper Manufacturing:

A. Raw Material Sourcing: The shift towards sustainability began with the responsible sourcing of raw materials. This included adopting certified sustainable forestry practices like FSC (Forest Stewardship Council) certification. Furthermore, the industry explored alternative fiber sources such as agricultural residues and recycled paper to reduce dependence on virgin wood.

B. Cleaner Production Techniques: Improved pulping methods played a crucial role in sustainability efforts. Oxygen delignification and the use of enzymes reduced the reliance on harsh chemicals. Additionally, the implementation of closed-loop systems minimized water usage and the generation of chemical waste.

C. Energy Efficiency: To reduce its carbon footprint, the industry embraced energy-efficient technologies like cogeneration and biomass energy. Recycled paper and cardboard became common feedstocks for paper mills, further reducing the environmental impact.

IV. Technological Advancements:

A. Digitalization: The advent of the digital age had a profound impact on paper consumption. Digital communication, document management systems, and paperless initiatives reduced the demand for traditional paper products. E-commerce also contributed to this shift, as electronic records and transactions replaced physical paperwork.

B. Circular Economy: Paper manufacturers began prioritizing the principles of the circular economy. This involved recycling and reusing paper products, thereby closing the loop on materials. Pulp and paper mills optimized their processes to recover and reuse materials and energy, minimizing waste and resource consumption.

| Also Read: Towards Net-Zero: Pulp and Paper Industry's Green Commitment |

V. Looking Ahead: The Road to Sustainability

As the pulp and paper industry continues its journey toward sustainability, there are several key initiatives on the horizon:

A. Innovative and Sustainable Materials: The industry is actively exploring and developing innovative, environmentally friendly materials to replace traditional paper products. These materials may incorporate alternative fibers or incorporate advanced technologies to reduce environmental impacts.

B. Renewable Energy Adoption: To reduce its carbon footprint, the industry is increasingly turning to renewable energy sources to power its mills. This transition involves investments in technologies like wind, solar, and biomass energy to reduce reliance on non-renewable resources.

C. Efficient Water Management: Further efforts are underway to reduce water usage and minimize environmental impacts through advanced treatment methods. This includes recycling and treating process water to minimize consumption and limit pollution.

D. Enhanced Recycling and Recovery Systems: The industry is committed to enhancing recycling and recovery systems to minimize waste. This involves optimizing processes to recover and reuse materials, reducing the need for new resources.

E. Stakeholder Collaboration: Collaboration with stakeholders across the supply chain is essential to ensure responsible practices are upheld. This includes working closely with suppliers, customers, and regulatory bodies to promote sustainability standards and initiatives.

In this ongoing journey, the pulp and paper industry remains dedicated to reducing its environmental footprint, embracing innovation, and collaborating with others to create a more sustainable future. These initiatives reflect a collective commitment to environmental stewardship and responsible resource management.

VI. Challenges and Future Prospects:

While the pulp and paper industry has made significant strides toward sustainability, it still faces challenges on its path to becoming more environmentally responsible. Some of these challenges include:

A. Resource Scarcity:

• The availability of sustainable wood sources continues to be a concern as global demand for paper products remains high.

• Finding alternative, non-wood fibers that can meet quality and sustainability standards is an ongoing challenge.

B. Energy Transition:

• Transitioning to renewable and low-carbon energy sources is crucial for reducing the industry's carbon footprint.

• Investments in technology and infrastructure for sustainable energy production require significant capital and commitment.

C. Waste Management:

• Effective management of paper waste, especially in regions with limited recycling infrastructure, remains a challenge.

• The development of innovative recycling and waste-to-energy technologies is essential.

D. Consumer Behavior:

• Changing consumer behavior to reduce paper consumption and increase recycling is a long-term endeavor.

• Raising awareness about the environmental impact of paper products can contribute to responsible consumption.

E. Sustainable Practices across the Global Supply Chain:

Maintaining sustainability standards across the entire supply chain, from sourcing raw materials to distributing end products, poses complex logistical challenges.

Despite these hurdles, the pulp and paper industry's future outlook is highly optimistic. Ongoing research and development efforts, international cooperation, and the pursuit of innovative solutions will be instrumental in overcoming these challenges. With an increasing emphasis on sustainability and responsible resource management, the industry is strategically poised to continue its evolution and make substantial contributions to a more sustainable and environmentally conscious future.

VII. Global Sustainability Initiatives:

Recognizing the need for collective action, the pulp and paper industry has actively engaged in global sustainability initiatives. These collaborative efforts aim to drive positive change and accelerate the transition toward more sustainable practices.

A. Forest Certification Programs: Organizations like the Forest Stewardship Council (FSC) and the Programme for the Endorsement of Forest Certification (PEFC) have established rigorous certification standards for sustainable forestry. Many pulp and paper companies participate in these programs, ensuring responsible sourcing of wood fiber.

B. Sustainable Development Goals (SDGs): The United Nations Sustainable Development Goals provide a framework for addressing global challenges, including those related to the pulp and paper industry. Industry stakeholders align their sustainability efforts with SDGs, such as responsible consumption and production and life on land.

C. Circular Economy Initiatives: The industry actively promotes circular economy principles, aiming to minimize waste and maximize resource efficiency.

Collaborative initiatives focus on designing products for recyclability, improving recycling infrastructure, and reducing waste.

D. Commitment to Carbon Emission Reduction: A significant number of companies within the pulp and paper industry have committed to ambitious carbon reduction goals in accordance with international climate agreements such as the Paris Agreement. These commitments are supported by strategic investments in multiple areas, including the integration of renewable energy sources, the deployment of carbon capture technologies, and the promotion of sustainable forest management practices. These initiatives underline the industry's dedication to lowering its carbon emissions and playing a constructive role in global climate efforts.

E. Industry Associations: Trade associations and industry groups play a vital role in coordinating sustainability efforts. They facilitate knowledge sharing, research, and best practices to help member companies improve their environmental performance.

These global sustainability initiatives demonstrate the industry's commitment to addressing environmental challenges collectively. By participating in these programs and collaborations, the pulp and paper sector continues to work towards a more sustainable future while aligning with broader global sustainability objectives.

Conclusion:

In summary, the transition of pulp and paper manufacturing from traditional to sustainable practices reflects the industry's resolute dedication to environmental responsibility. Through conscientious raw material sourcing, cleaner production methods, improved energy efficiency, and the integration of innovative technologies, the sector has achieved noteworthy progress in curbing its ecological footprint. As global awareness of environmental challenges continues to mount, the industry is poised to persevere in its quest for even greater sustainability, ensuring a lasting and positive impact on the planet for generations to come.