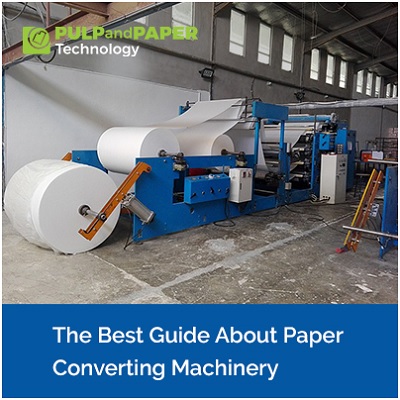

The Best Guide for Paper Converting Machinery

The word "paper conversion" refers to the processes used to convert raw paper material into other products. This raw material can be in a sheet or roll form. These finished products for e.g. books, packaging, newspapers, labeling, etc, are used in almost every sector and industry. An appealing fact you would learn is that the technologies employed in paper converting and printing operations frequently depend on bearings to get accurate, precise, and smooth performance.

The worldwide market for paper converting machines was assessed at US$41.4 billion for the year 2020, and is probably going to project at US$49.7 billion by 2027, developing at a CAGR of 2.7% over the expected period 2020-2027.

The paper converting and printing industry remains a major player in the global economy, despite the growth of the digital world. From newspapers to books to shipped and mailed items, paper products are an essential part of our day-to-day lives. The entire paper conversion process starts with raw material and ends with a finished product. It includes the following below steps:

- Collecting raw fibers and melting it into pulp

- Straining, bleaching, flattening, and drying the pulp into a continuous paper roll

- Cutting the master paper roll into more manageable sizes

- Cutting and shaping the lesser rolls in the preferred shape and size.

There are several techniques for completing the latter two steps of the paper conversion process. The two most common are -

- Slitting/Rewinding

- Precision Roll Sawing

Benefits of Paper Conversion

The paper converting and printing industry affects our day-to-day lives in several ways with regard to the following:

- Products/Packaging: Several products used regularly are made from paper. In the consumer sector, we frequently use books, newspapers, bags, magazines. While most industrial and commercial companies use some form of paper packaging like for boxes, packing paper, cartons, etc) for their products.

- Improve environmental footprint: The industry has made significant advancement toward improving its ecological impression. Besides reducing its intake of fossil fuels during the paper products production, it has created methods for reusing old and utilized paper items into new materials and products. The latter is vital for the reduction of the overall size of landfills.

How Does A Paper Converting Machine Work?

A paper converter takes one form of a paper and makes it into another paper product. For e.g. A large bundle of kraft paper could be printed, coated, and sheeted into custom-specified sandwich wrappers for a restaurant.

Common Paper Converting Processes

Some of the common paper converting processes are -

- Roll Slitting - In this process, the paper rolls start off in wide master rolls. If you require a narrower roll, such as a roll for custom kraft paper table covers, a paper converter cuts it accurately to your desired width.

- Sheeting - A sheeter gets a roll of paper and turns it into sheets of paper. The only thing you need to think about is what size of custom paper sheets you want and it can be produced to your precise specifications.

- Flexographic printing - This printing method is usually used to print disposable containers and cups, paper sacks, envelopes, folding cartons, candy and food wrappers, and corrugated containers. Besides, clients looking for creative paper solutions usually find that flexo printing is an essential part of their custom projects.

- Coating - In this process, the paper coating takes an usual paper product and converts into something with a particular purpose or application. You may need coating to produce tags and labels, specialty tapes, or water or grease impermeable papers for the food industry.

- Laminating - Just like coating, this process even takes an ordinary paper and converts it into something special. If you require metallized paper for decorative packaging, point-of-purchase displays, or gift wraps, you may require paper laminating process.

Types of Paper Converting Machinery

The different paper converting machinery involved in the paper converting and printing industry are -

- Slitter/Paper rewinding machine - this is a kind of paper rewinding machine/paper winding machines. The slitters are of two types - roll saw and rewind slitting. In rewind slitting, the material is pulled out from the roll and cut into required length and then rolled it to the other roll, whereas the roll saw machine is a slicer that slices the roll into several pieces. The latest and the most highly developed equipment in the paper converting machine field is the Roll Saw Razor or Roll Razor, which can process a roll four times faster than a rewinder for cutting down rolls into lesser ones. But it does not rewind into new cores.

- Paper Sheeter Machine - The paper sheeter machinery/paper sheet cutting machine cut the paper sheets into an exact size. They are extremely precise and provide the paper stacks in a regular size for further usage into production or for the end user.

- Roll Winding Machine - The roll winding machine is used extensively in various industries. These machines are made available to the customers in various specifications and can even be customized as per the specified details.

- Paper and Folding Carton Sheeter - The versatile and high-speed paper and folding carton sheeter enables us to quickly produce high quantities of accurate sheet sizes for accurate production runs, optimizing efficiency, and minimizing waste. This also allows us to buy paperboard directly from the mills, providing us a price advantage over purchasing from paper houses.

Paper Rewinder Machine Manufacturers

The top three largest paper rewinder machine manufacturers are relatively unchanging these days. We have listed the top five companies that are both well-liked and accepted by their competition in their respective marketplaces.

The company designs and manufactures high-tech customized machines like sheeters and winders for the cardboard, paper, specialty papers, and security paper converting industry. Pasaban is focused on providing the paper industy with tweaked, excellent converting machines and solutions. The organization offers an all-in-one solution giving extensive solutions that incorporate different equipment like sheeters, winders, and ream wrappers.

| Also Read: Optimizing Production: The Evolution of Paper Converting Machinery |

Mitsubishi Heavy Industries Ltd

Mitsubishi Heavy Industries Group has been providing advanced machinery for the pulp and paper business since 1956. The company exports its machinery to over 40 countries, sustaining a major share of the market globally. Mitsubishi continues to develop the novel technologies to advance the quality of the boxes, productivity, and ease of operations for its clientele.

| Also Read: Innovations in Papermaking Machinery: A B2B Perspective |

Paper Converting Machine Company

With more than a century of experience in machine design, service, and manufacturing, Paper Converting Machine Company is an emerging global leader in tissue converting packaging, bag converting, nonwovens technology, and flexographic printing. The company has three major production centers in the U.S, U.K, and Italy. PCMC is only equipped to provide its clients with a wide range of automated converting solutions. PCMC provides machinery for several industries including tissue converting and packaging, nonwovens, and flexographic printing.