Articles

OraCrepe 30: when creping gets tough, the tough get going!

Creping is not magic: the physical properties of a tissue paper sheet are the result of the mechanical process that determines the lower density of fibres and their greater calliper. There is no secret recipe to obtain the desired “hand feel”, and no tricks are deployed in reaching the required density; these are simply the desired characteristics resulting from precise choices made during various stages in production.

Creping is therefore a complex interaction of many factors. Tissue makers have to consider some of the more critical factors, such as the selection and management of fibres, the choice and the monitoring of the most appropriate Yankee coating chemicals, the drying strategy, the crepe pocket geometry, the choice of adequate crepe blade material, and so on.

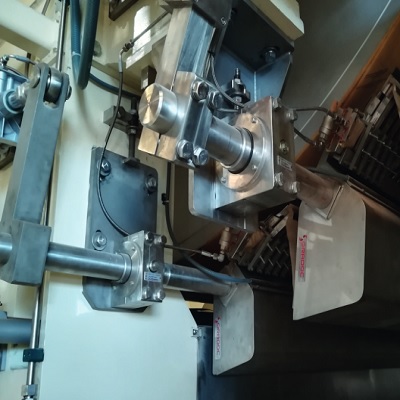

The right creping system is pivotal in the production process, and that is why Oradoc has constantly been working to improve creping performances in recent decades, striving to find solutions to issues that may otherwise adversely affect the creping process.This continuous effort has led us to launch OraCrepe 30 – a controlled-flexibility pneumatic creping blade holder that adapts its profile to the Yankee cylinder crowning, and one that has now gone a step further towards a more efficiently performing system; it entails a series of important benefits.

The ‘30’ version of the OraCrepe features the usual flexible system, along with an innovative open, yet compact design with a cartridge that reduces dirt accumulation and thus remains cleaner for longer, whilst incorporating an easier blade and stick-out change mechanism. Moreover, the new version can even be installed on a pre-existing, earlier version of an OraCrepe blade holder.

For More Information, Click Here..