In December of 2023, Woodgrain acquired Trimco Millwork and effective today Trimco Mill...

Paper Machine 1 (PM1), which specialises in the production of security papers, has been...

Metsä Group has entered into an extensive cooperation with international technolog...

Valmet will deliver a major boiler rebuild to E.ON’s Steven’s Croft biomass...

The new tissue machine is supplied by RePlus Tissue

The new...

Martco, LLC, parent company for timber sourcing and manufacturing company RoyOMartin, a...

The pulp and paper industry plays a vital role in modern society, providing essential products such as paper, cardboard, and various packaging materials. However, this industry is also known for its significant environmental impact, particularly in terms of waste generation and management. In recent years, there has been a growing emphasis on optimizing waste management practices within the pulp and paper sector to reduce environmental harm and improve overall sustainability.

In the realm of industrial processes, paper production stands as a vital pillar supporting modern society. From books to packaging materials, newspapers to sanitary tissues, paper products are integral to our daily lives. At the heart of this industry lies chemical pulping, a complex yet pivotal process in the journey from raw materials to finished paper goods.

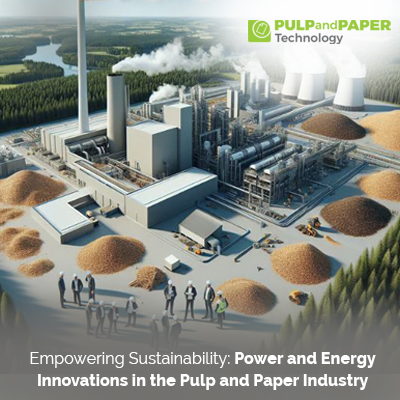

In today's rapidly changing world, the push for sustainability has become more important than ever. And one industry that's been working hard to answer the call is the pulp and paper industry. With advancements in technology and a growing awareness of environmental responsibility, this industry is embracing power and energy innovations to create a greener future.

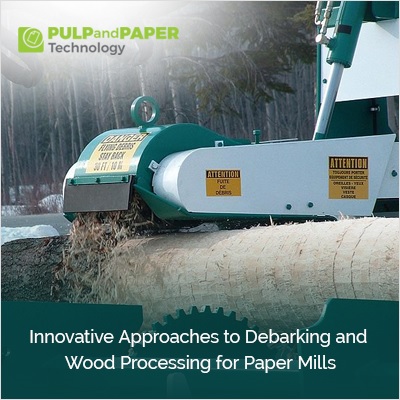

Today, paper mills are under increasing pressure to meet the growing demand for paper products while minimizing their environmental impact. To achieve this, companies are adopting innovative technologies and strategies that optimize the debarking and wood processing processes. In the past, paper mills relied on traditional methods for debarking and wood processing. Manual labor was the primary method, with workers using handheld tools to remove the bark from the logs

In the world of modern paper manufacturing, the role of adhesives and starch cannot be underestimated. These two components play a crucial role in ensuring the quality, strength, and durability of paper products that we use daily. Adhesives are used in various stages of the paper-making process, from the initial bonding of fibers to the final lamination and coating. They help create a strong connection between the fibers

"The Silyzer 300 is Siemens Energy’s latest product line in our portfolio of double-digit megawatt electrolyzers. It has several features that make it well suited for today’s green hydrogen production plants"

"AFT's proprietary simulation software called SimAudit™ helps in the evaluation and selection of appropriate equipment to fit the specific customer needs. We can simulate individual unit operations or an entire process line to accurately predict the benefits of our proposed solutions".

"As manufacturers, we ought to offer machines that are reliable, customizable and affordable so our customers can be competitive in this global landscape".

"We at Messe Muenchen India have been bringing the thought leaders, technology providers and government officials together at one platform to offer right technologies".

"We offer a complete package of deliveries from stock preparation lines to paper machines to papermaking auxiliary chemical plants and naturally to professional engineering services"

Crown Paper Mill has decided to invest in a second Valmet’s Advantage DCT tissue line including an extensive automation package, flow control valves a...

Argentinian leading packaging paper and tissue producer UnionPel selected Toscotec to supply a technological upgrade of PM1 at their Pacheco mill in t...

International technology group ANDRITZ has received an order from Moorim P&P, South Korea, to upgrade an evaporation plant at its Ulsan mill.

DS Smith, a world leader in sustainable packaging solutions, has unveiled a £48 million investment in a new fibre preparation line (F-line) at their K...